请输入正确的账号名!

密码格式有误请验证!

请输入正确的账号名!

请输入正确的账号名!

请输入正确的单位名称!

请输入....!

请输入....!

请输入....!

请输入....!

请输入....!

目前您的账号暂时还不能进行登录哦~

对此我们深感抱歉!但还请您耐心等待审核通过

注册信息审核通过后我们将会在第一时间以邮件的方式通知您

请输入正确的账号名!

请输入....

请输入....!

请输入....!

请输入....!

密码格式有误请验证!

密码格式有误请验证!

请输入....!

AIPOD is a universal platform that is independently developed by Nanjing Tianfu Software Co., Ltd for intelligent design optimization. AIPOD provides SilverBullet, an industry-leading intelligent optimization algorithm designed to remove pain points in industrial design, such as high computational costs of numerical simulation. The senior engineering design experts of Tianfu have a unique and thorough understanding of product R&D and design. As a result, they are able to equip AIPOD with outstanding optimization effect, simple and convenient operations, and high optimization efficiency. AIPOD can help the design team efficiently find better solutions for various scenarios, including structural, fluid, thermodynamic, acoustic, and multiphysics coupling scenarios.

HIGHLIGHTS

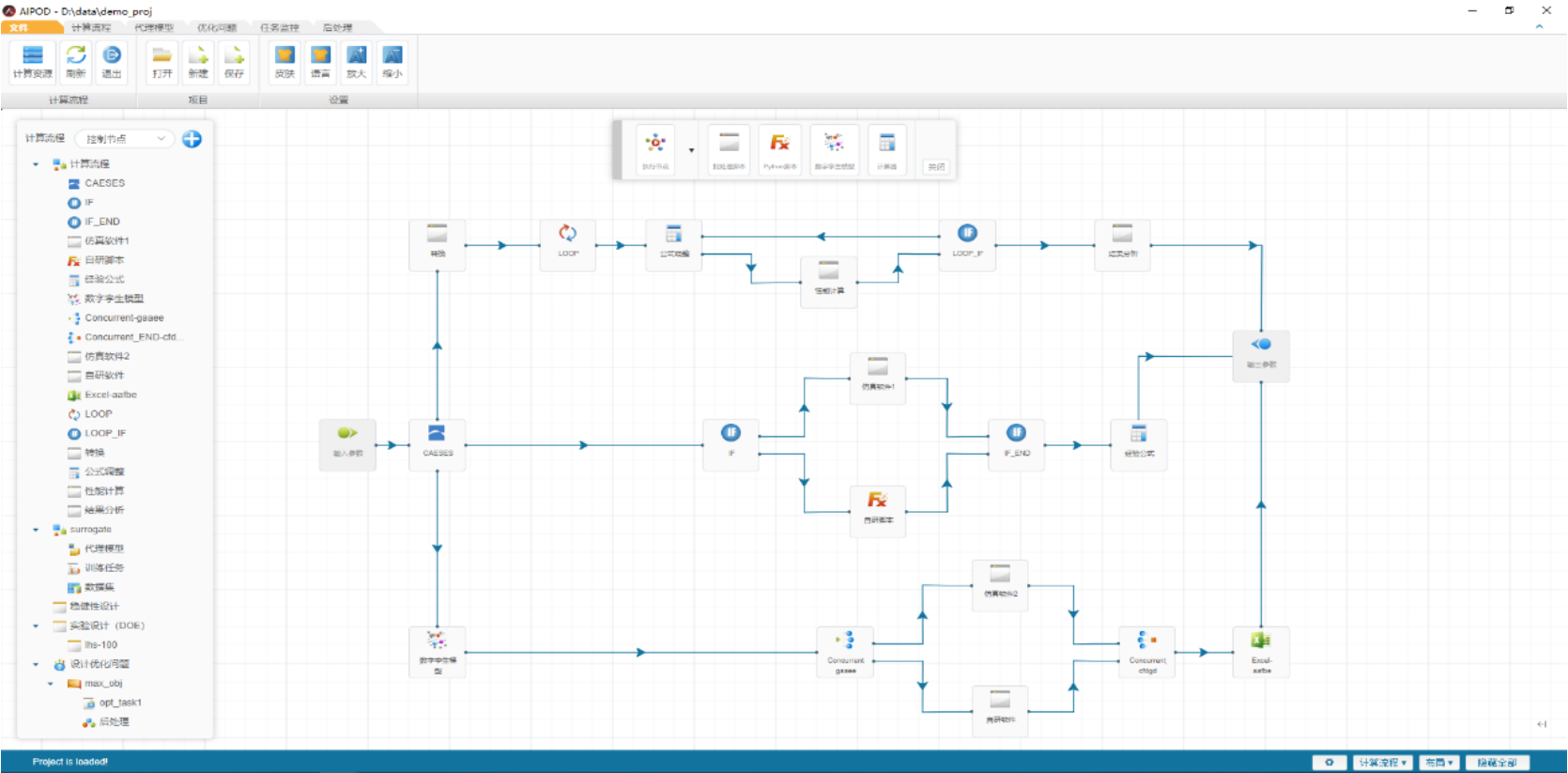

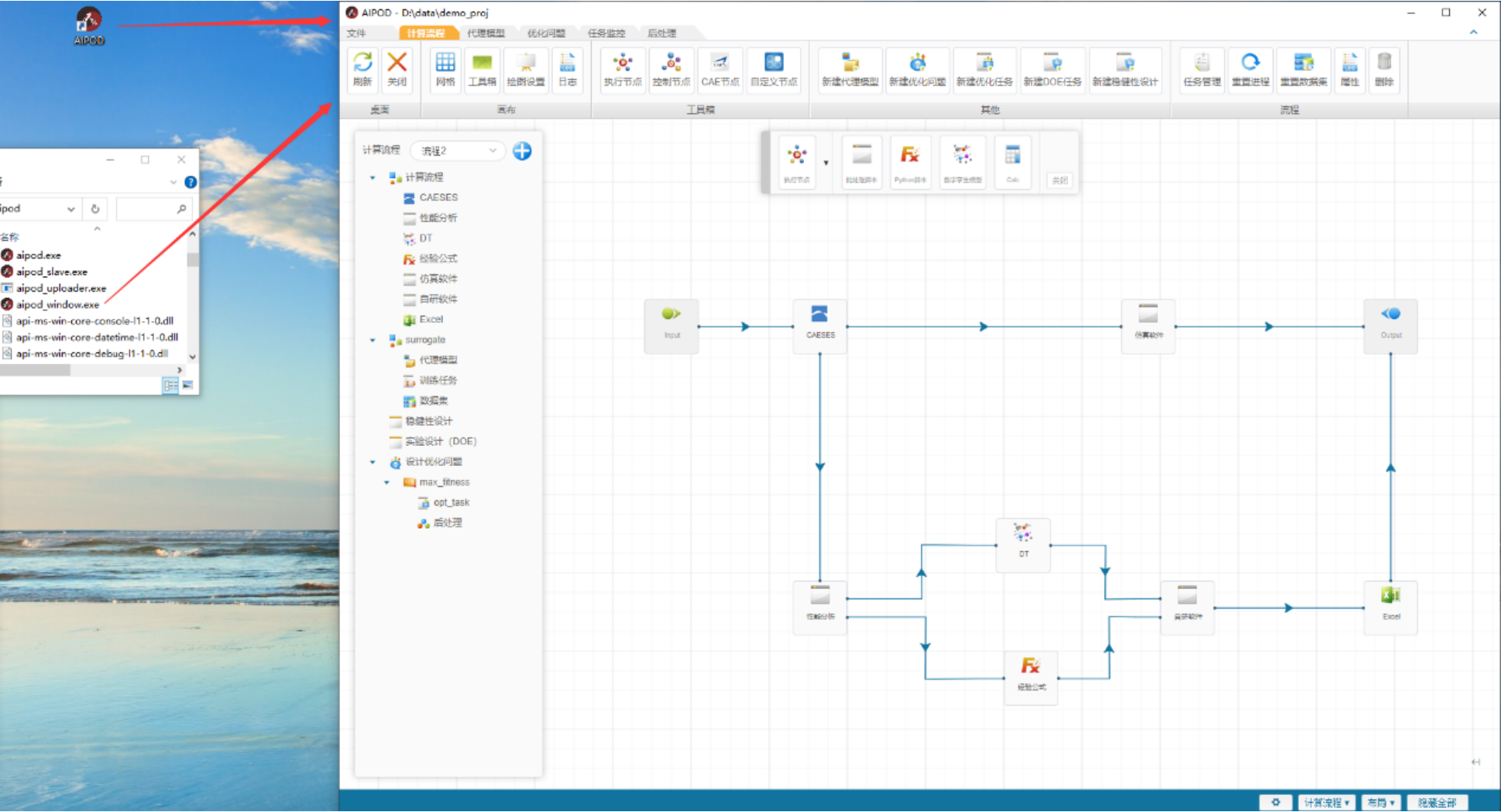

(1) Powerful computational process modeling: AIPOD provides a GUI that can be used to define the computational process. In a computational flowchart, users can easily call commercial software and dynamic libraries or directly embed experience formulas by using scripts. This way, users can build computational process models with arbitrary complexity to develop an automatic computational process that can be called by the optimization engine.

Powerful computational process modeling

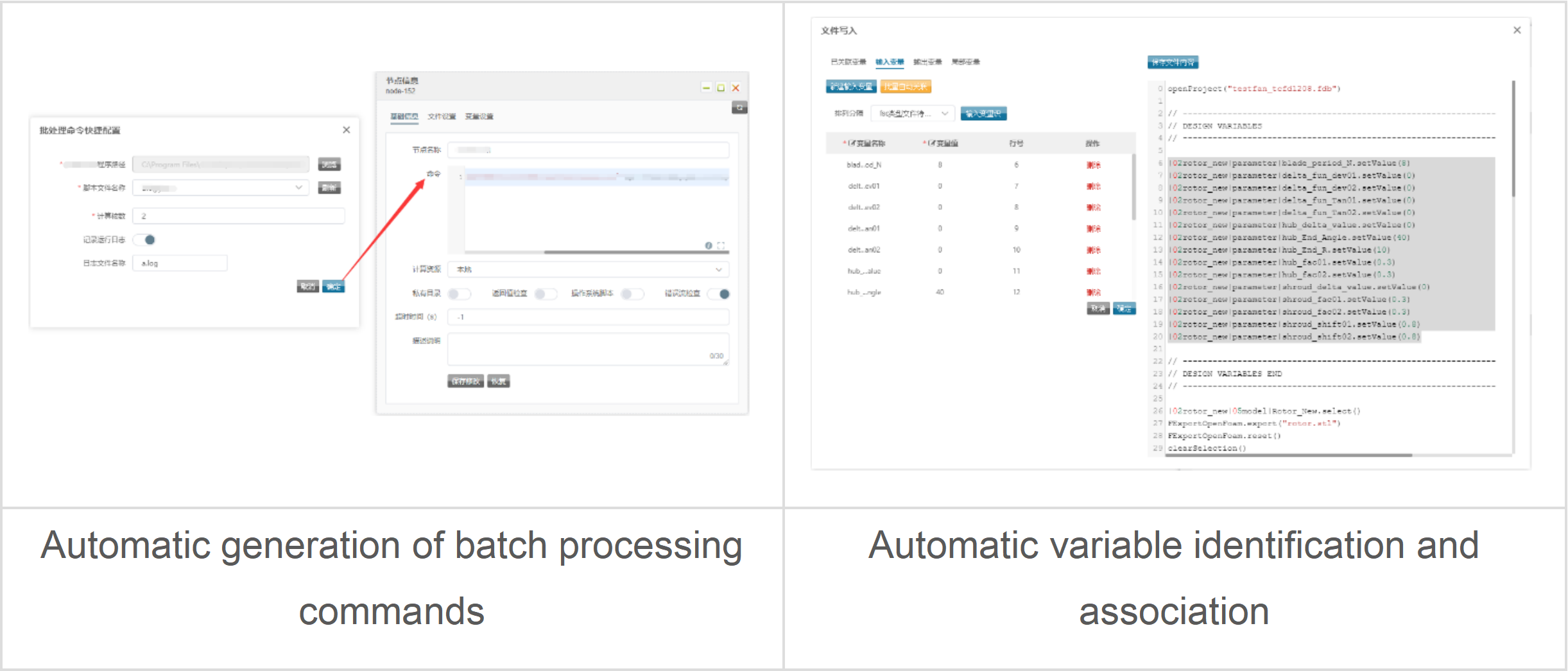

AIPOD provides a computer-aided engineering (CAE) node toolbox that includes mainstream CAE software. By using the APIs of custom commercial software, users can configure AIPOD to generate batch processing commands and identify variables after simple operations. This ensures quick integration of the computational process.

Figure 2 Quick configuration of CAE nodes

As shown in figure 3, AIPOD also provides a control node toolbox that contains the IF, Loop, Concurrent, and other process control nodes.

Figure 3 Control node toolbox

The IF node executes branches in the computational process based on different preconditions. The subsequent computational operations vary based on the precondition. The Loop node performs loop execution of branches in the computational process. The Concurrent node performs concurrent execution of branches in the computational process, thereby maximizing computing resources.

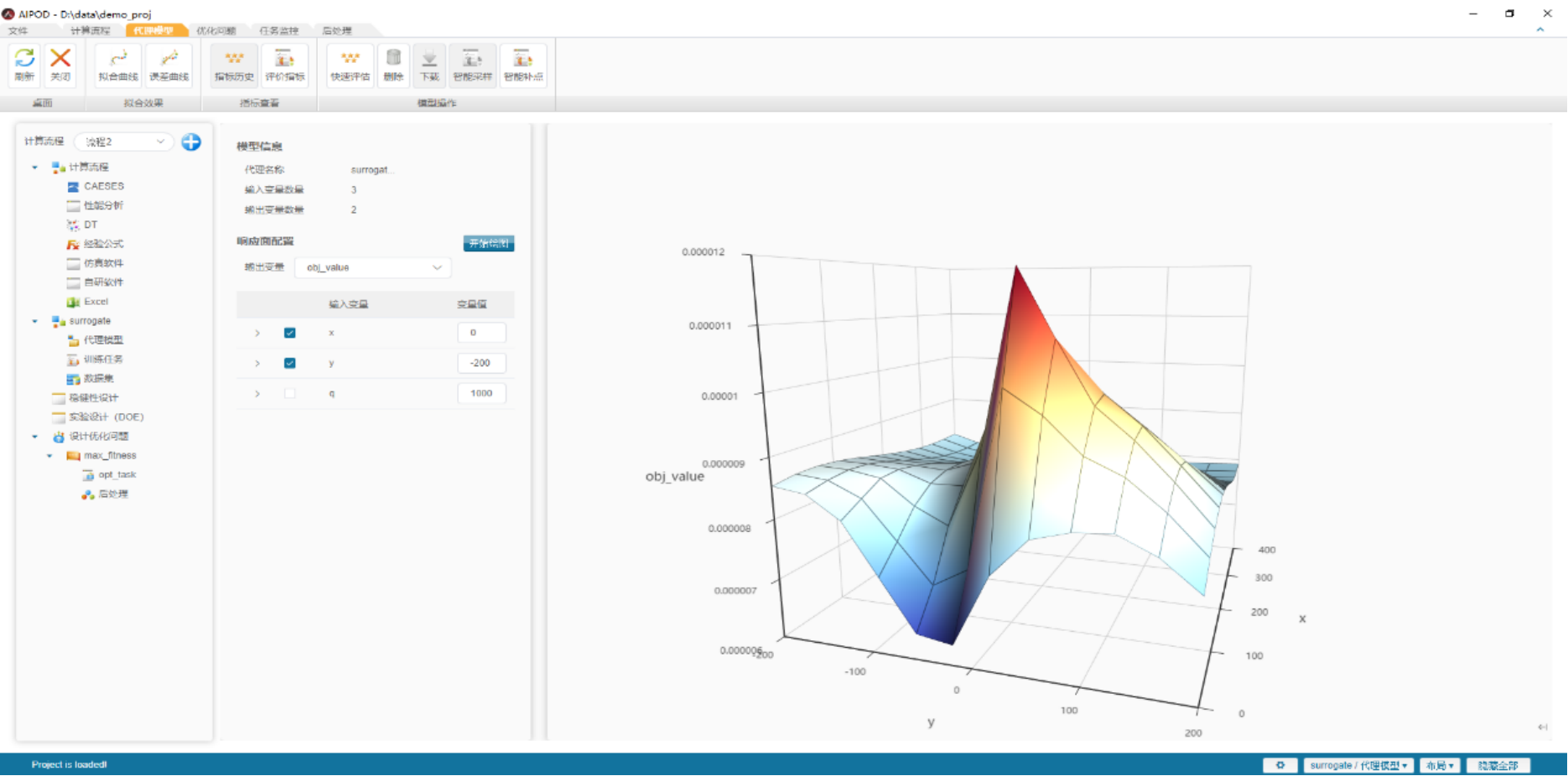

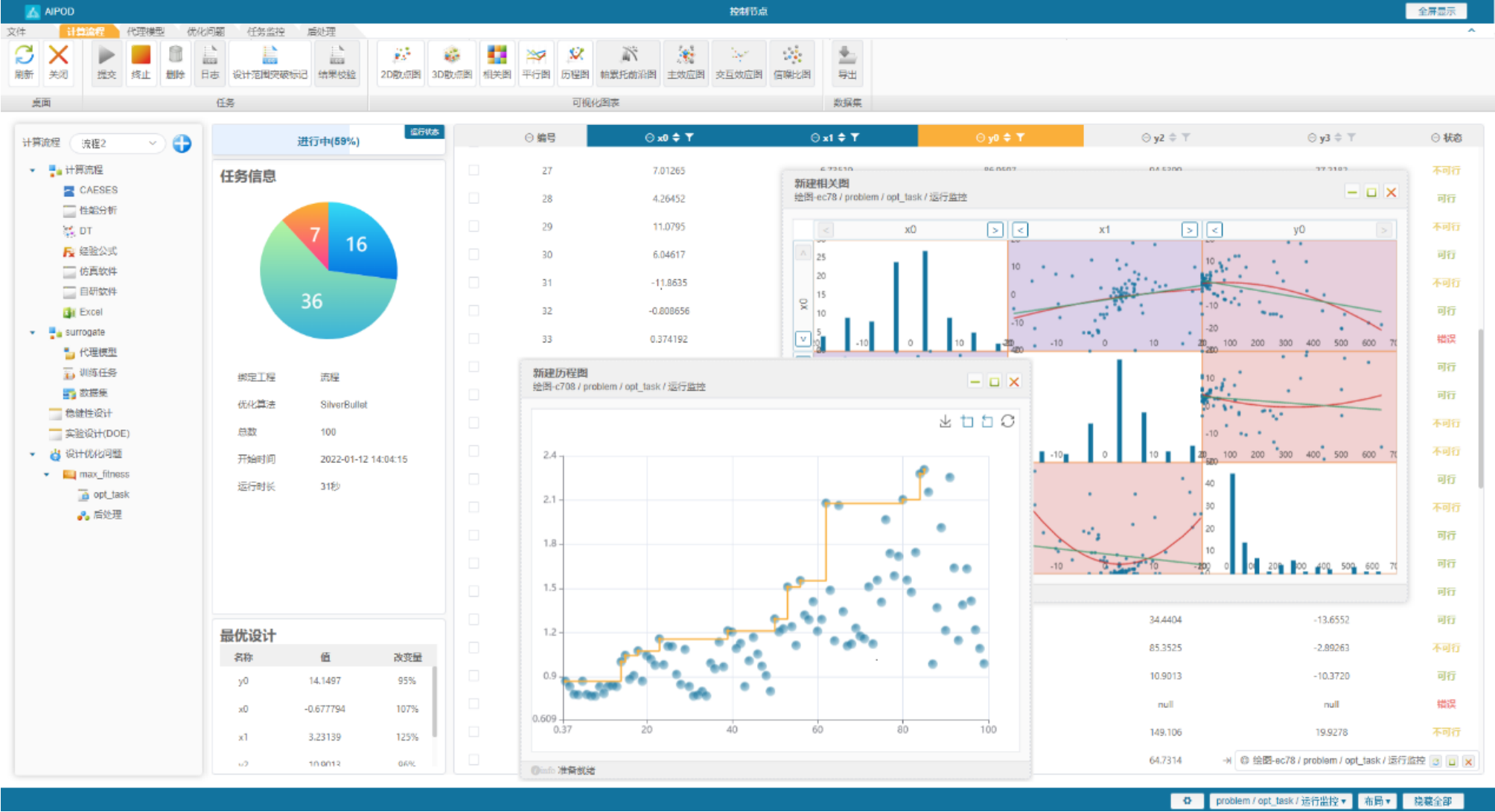

(2) Brand-new agent optimization and acceleration module AIAgent: AIAgent can connect to the computational process for intelligent data sampling and use the self-developed machine learning algorithm of Tianfu to train agent models to accelerate design optimization. The machine learning algorithm of AIAgent comes from the data modeling platform of Tianfu. The core of the algorithm is the self-developed hyperparameter learning framework of Tianfu. Compared with the traditional response surface methodology (RSM) and Kriging model, AIAgent has a stronger representational capability for complex issues, requires fewer data sets, and is easier to use. In addition, trained models can be exported, reused, and managed as the core knowledge of enterprises, thereby improving the quick design optimization capabilities of enterprises.

Figure 4 One-click building of reusable and high-precision agent models in AIAgent

(3) SilverBullet algorithm with intelligent search capabilities: The SilverBullet algorithm is developed to help reduce the high computational costs of numerical simulation in industrial design. This algorithm achieves the maximum performance with the minimum computational costs and is therefore suitable for small-scale computing scenarios in which only about 100 times of computation are required due to cost restraints. The SilverBullet algorithm integrates intelligent sampling, coupling optimization, and a set of core metrics to dynamically balance the performance of global optimization and local search. This improves the high-efficiency optimization performance in small-scale computing scenarios. The SilverBullet algorithm has the following two features:

a. Automatic adaptation to optimization scenarios and zero usage barrier

The SilverBullet algorithm has high adaptability. To start an optimization process, users need only to specify desired computational costs without setting any hyperparameters. This dramatically lowers the barrier to using AIPOD.

b. Intelligent bound-break feature

The unique, intelligent, and optimized search capability of SilverBullet can solve the dilemmas of imprecise parameter ranges. If the value range of a variable is imprecise, SilverBullet automatically determines whether to break the value range boundaries to obtain a better design solution without increasing the search costs.

(4) SilverWing algorithm with the advantages of coupling agent models and solvers: The SilverWing algorithm integrates various technologies, such as high-precision agent learning (AIAgent), reinforcement learning (RL), and heuristic optimization. AIAgent provides carriers for activating and using the existing data of users. In addition, AIAgent finds patterns in a massive volume of data, promotes continuous optimization and efficiency of industrial processes, achieves closed-loop accumulation of designs, and accelerates basic innovation. The RL and heuristic optimization technologies ensure the rapid output of efficient design scheme sets within a controllable period of time.

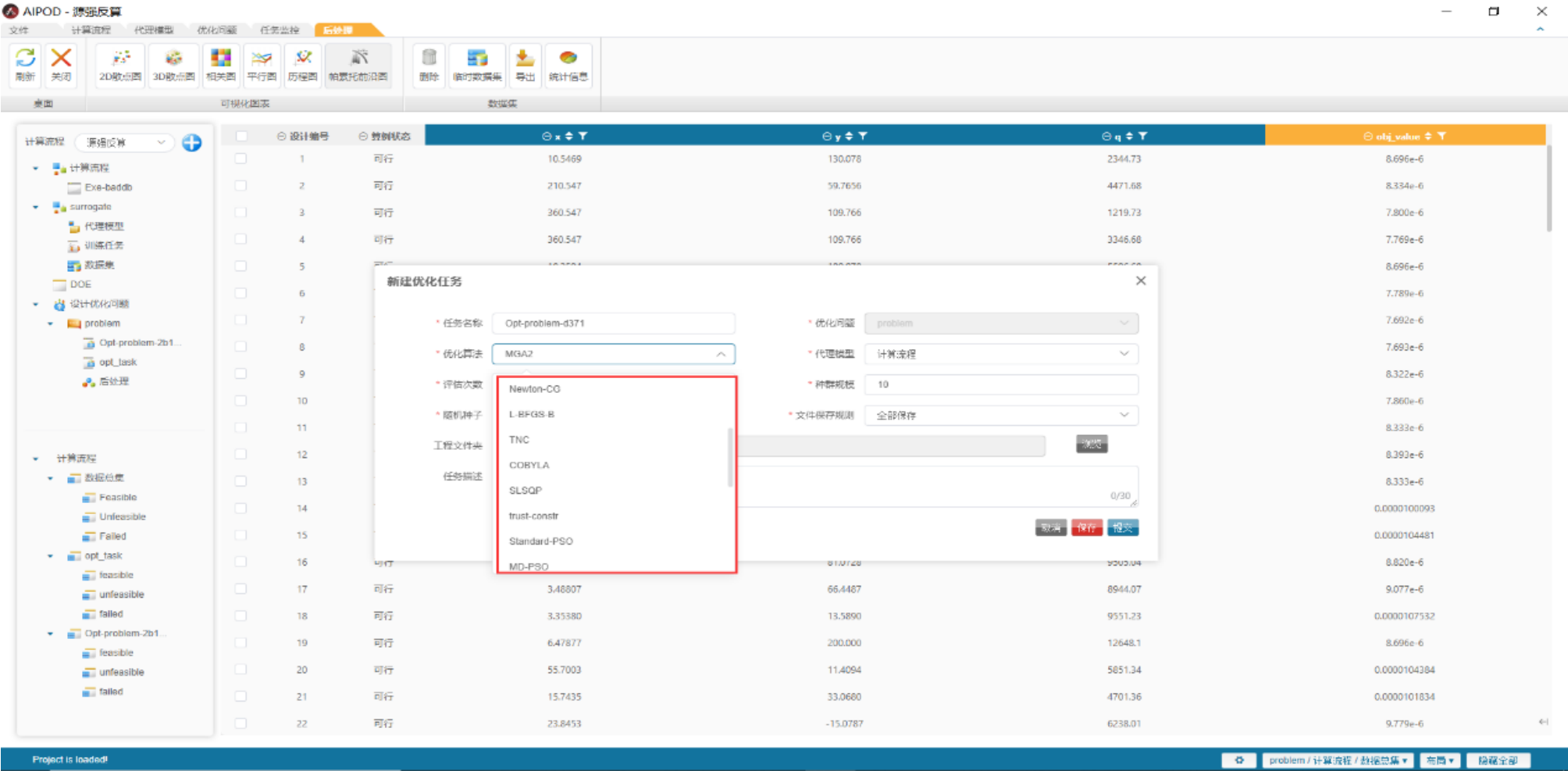

(5) Abundant optimization algorithms: In addition to the SilverBullet and SilverWing algorithms mentioned before, AIPOD integrates 22 single-objective optimization algorithms, including gradient methods such as conjugate gradient (CG) and evolutionary algorithms such as modified genetic algorithm (MGA). AIPOD also integrates four multi-objective optimization algorithms based on the decomposition (MOEA/D) framework. The NSGA3 and MOEA/D optimization algorithms can optimize discrete variables.

Figure 5 Abundant optimization algorithms

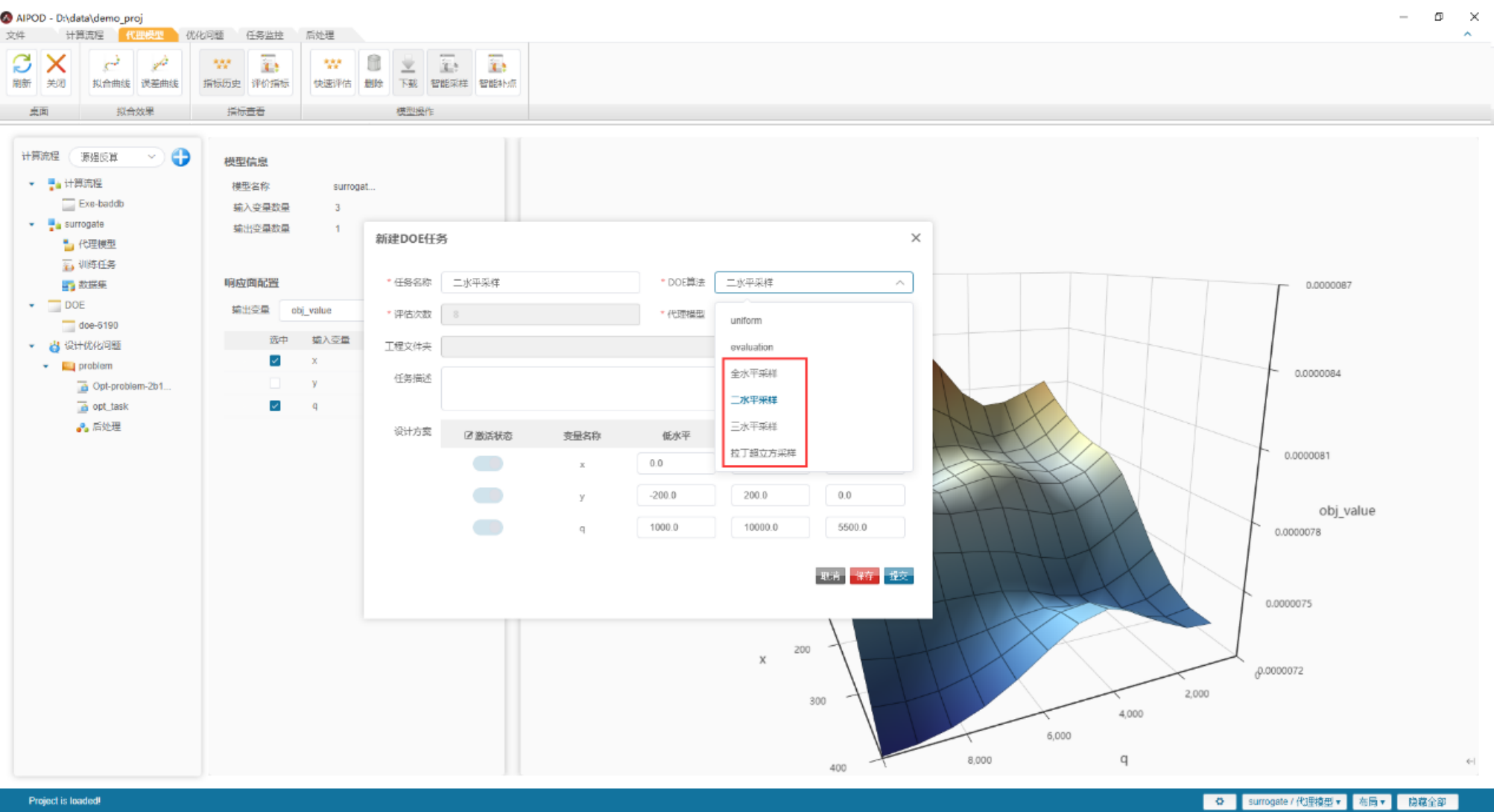

(6) Abundant design of experiments (DOE) algorithms: AIPOD is embedded with various DOE algorithms, such as uniform sampling, two-level sampling, Latin hypercube sampling (LHS), and user-defined sampling. Moreover, AIPOD supports DOEs that contain discrete variables.

Figure 6 Abundant DOE algorithms

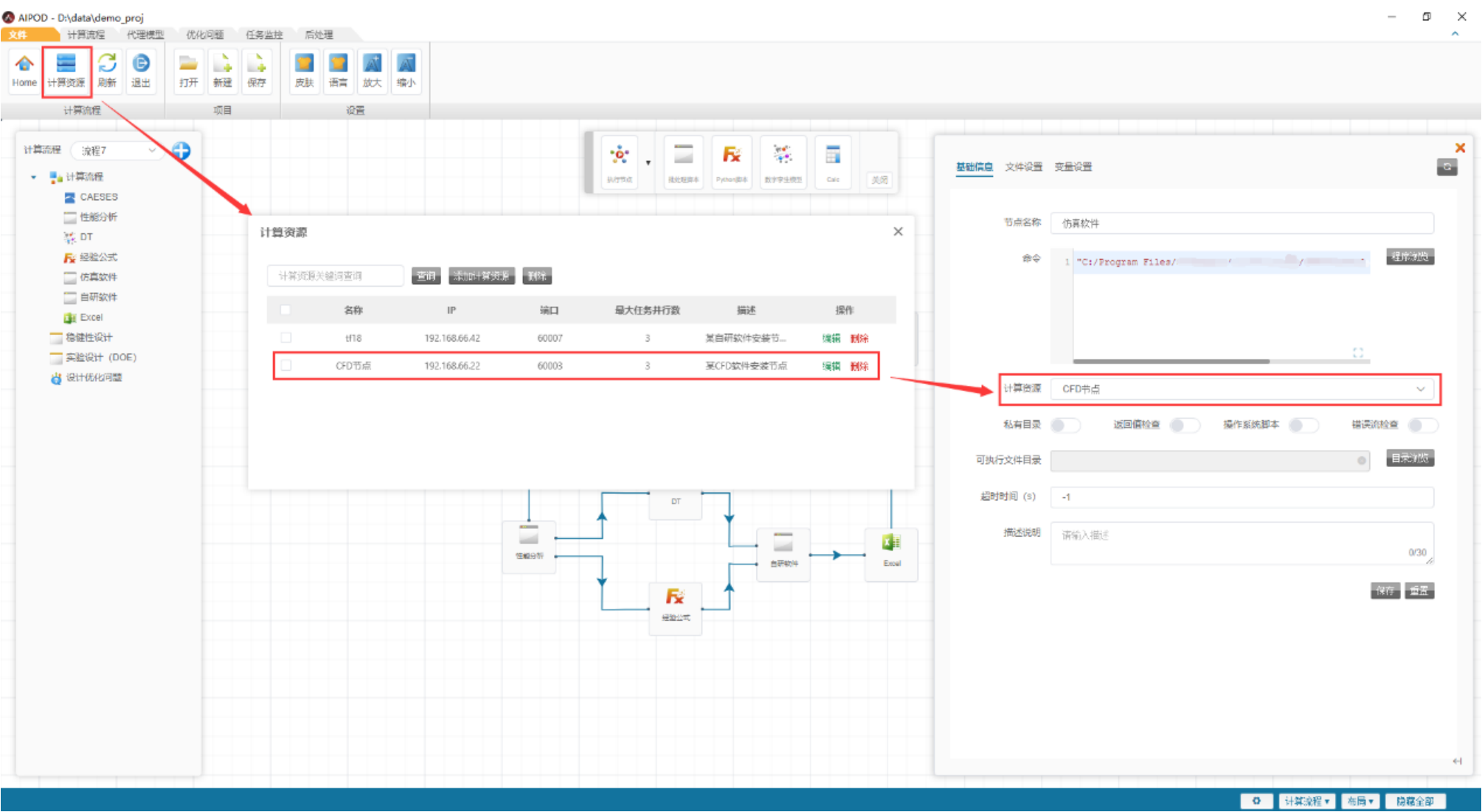

(7) Distributed computing: AIPOD can call software on different computers in a single computational process to efficiently utilize computing resources. To call the software installed on a computer for a process on the AIPOD primary node, you need only to enable the AIPOD secondary node service on the computer. You do not need to install auxiliary tools or configure extra parameters. The process is simple and convenient.

Figure 7 Distribution configuration

(8) Various interaction methods and adaptation to multiple operating systems: AIPOD provides standalone and server editions adaptable to Windows and Linux operating systems. The server edition uses web-based UIs and has an operating system that does not need a GUI. Therefore, users can deploy AIPOD on a server to utilize the powerful hardware resources of the server. Users can access AIPOD through a browser anytime, anywhere to manage the computational process, submit optimization tasks, view the running status of tasks, and analyze the optimization results. This way, users can effectively control their optimization tasks.

Figure 8 AIPOD startup on a client

Figure 9 Remote monitoring of optimization tasks

CASES

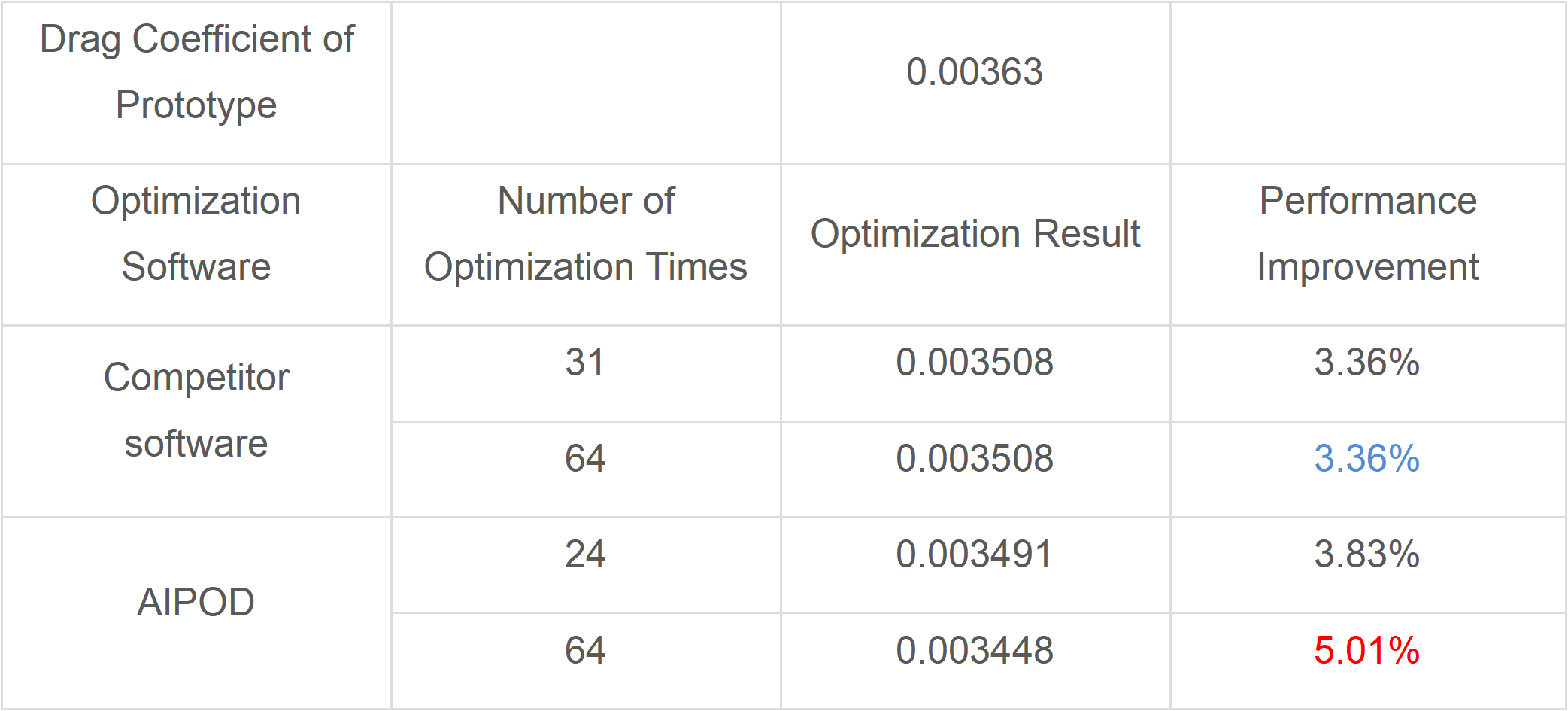

(1) Ship hull optimization 1

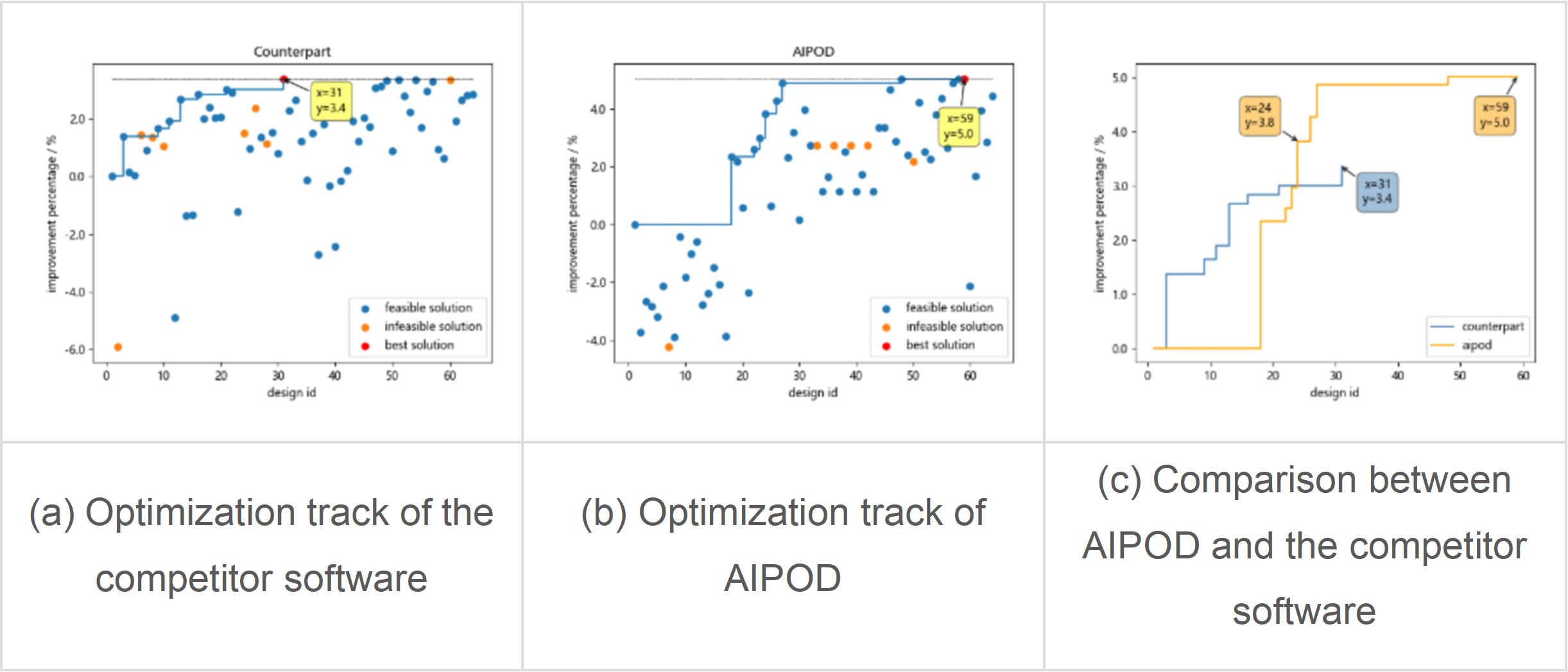

This case has six design variables. The target variable is the minimum drag coefficient. There are two constraints, and the number of computational fluid dynamics (CFD) calling times is limited to 64. Table 1 describes the optimization process. After 64 times of optimization, AIPOD improves performance by 5.01%, surpassing the competitor software that improves performance by only 3.36%.

Table 1 Key data in the optimization process of AIPOD and the competitor software

The following figure shows the optimization process of AIPOD and the competitor software. The competitor software showed rapid performance improvement in the early phase. However, its subsequent performance improvement is slow, and no further improvement was observed after the local extremum was reached.

Optimization process of AIPOD and the competitor software

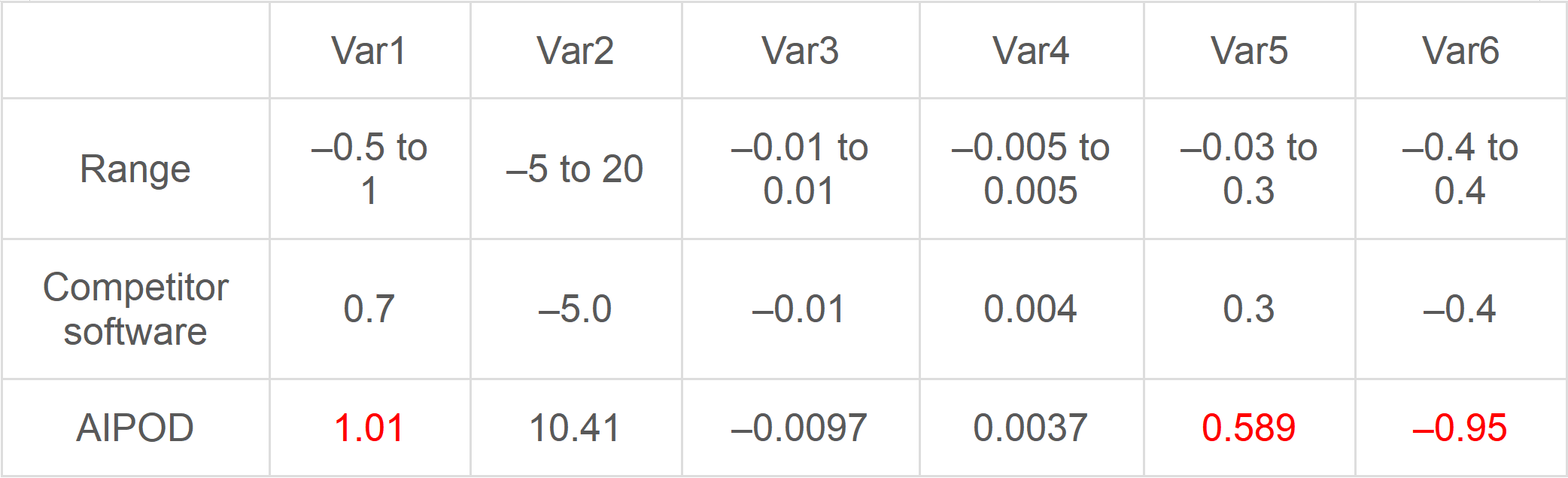

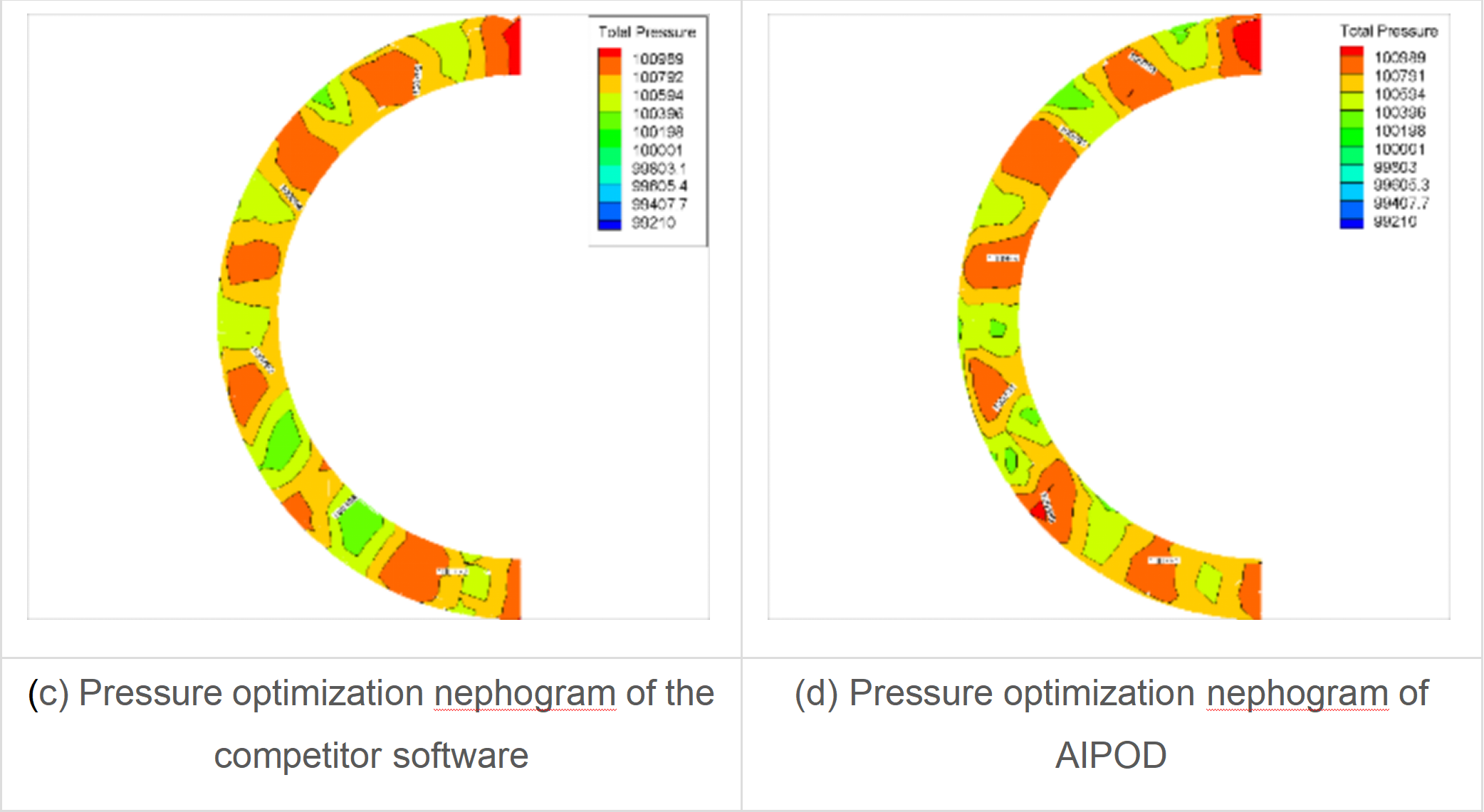

In this case, the intelligent bound-break feature of AIPOD is enabled for optimization. As shown in Table 2, the optimization engine of the competitor software does not extend the range for efficient and feasible optimization if the design parameter ranges are improper. By contrast, the SilverBullet algorithm can quickly break the optimization barriers caused by improper range settings even in small-scale computing scenarios in which optimization is performed only 64 times.

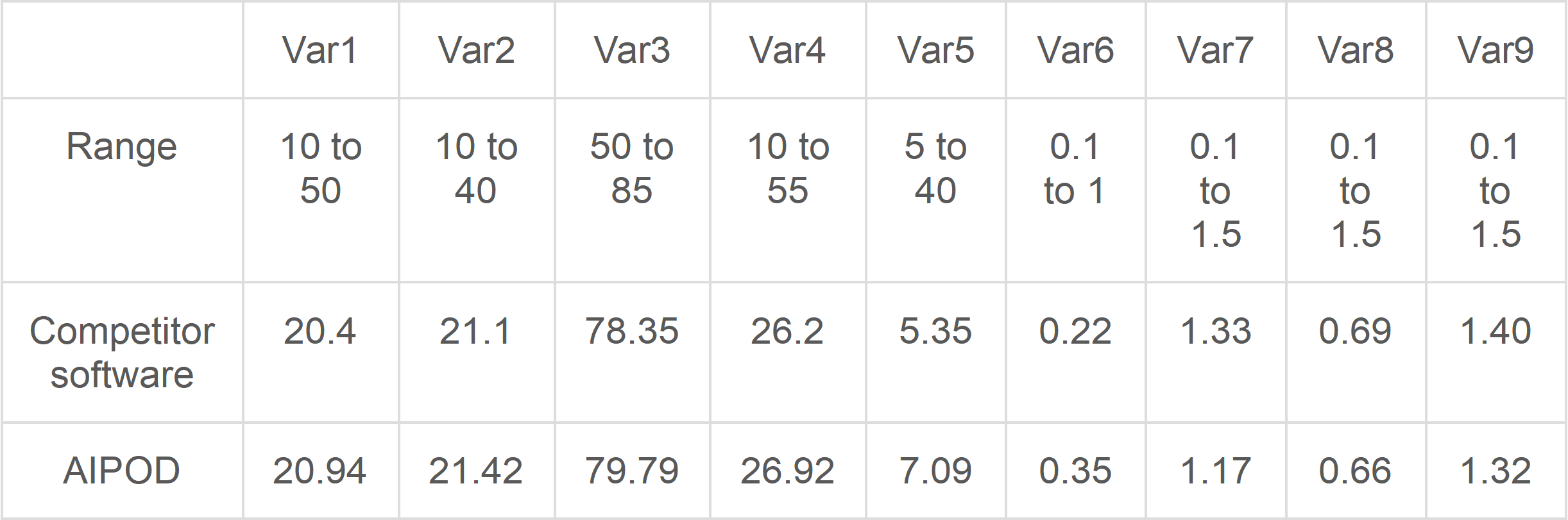

Table 2 Pre-defined value ranges and the values used by AIPOD and the competitor software to generate the optimal design

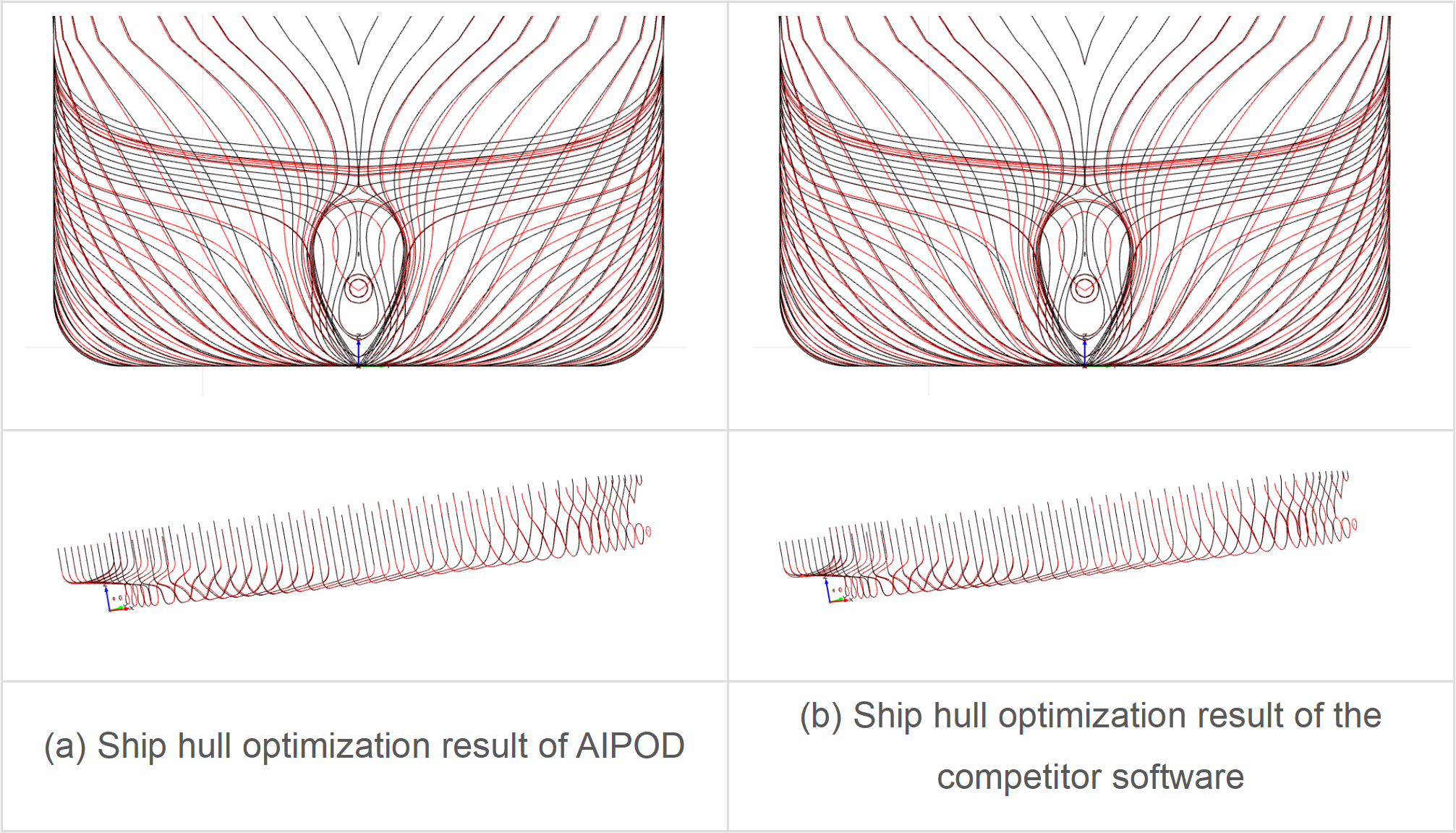

The following figure shows the ship hull optimization results of AIPOD and the competitor software.

Ship hull optimization results

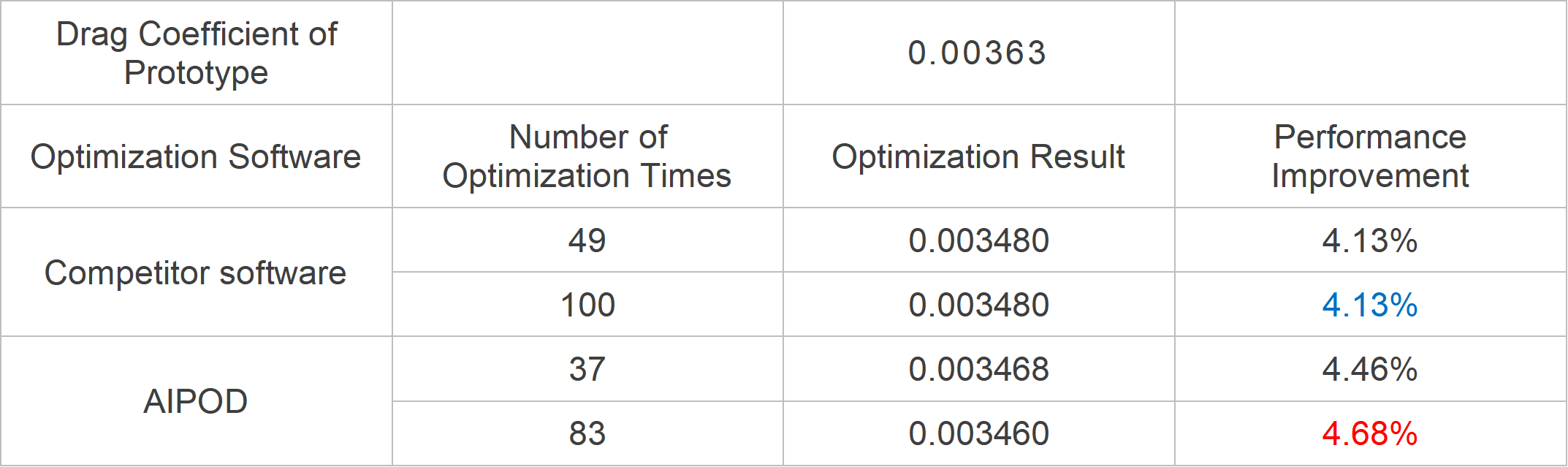

(2) Ship hull optimization 2

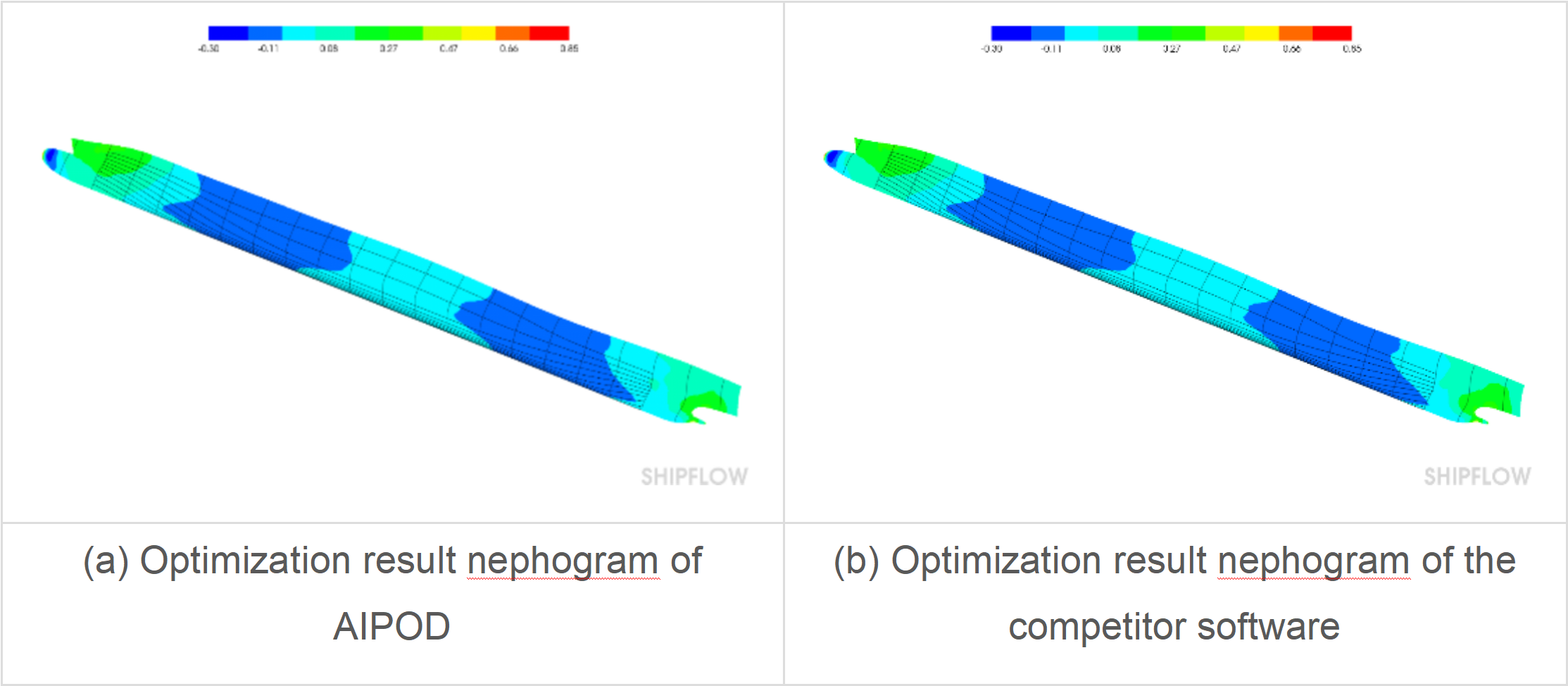

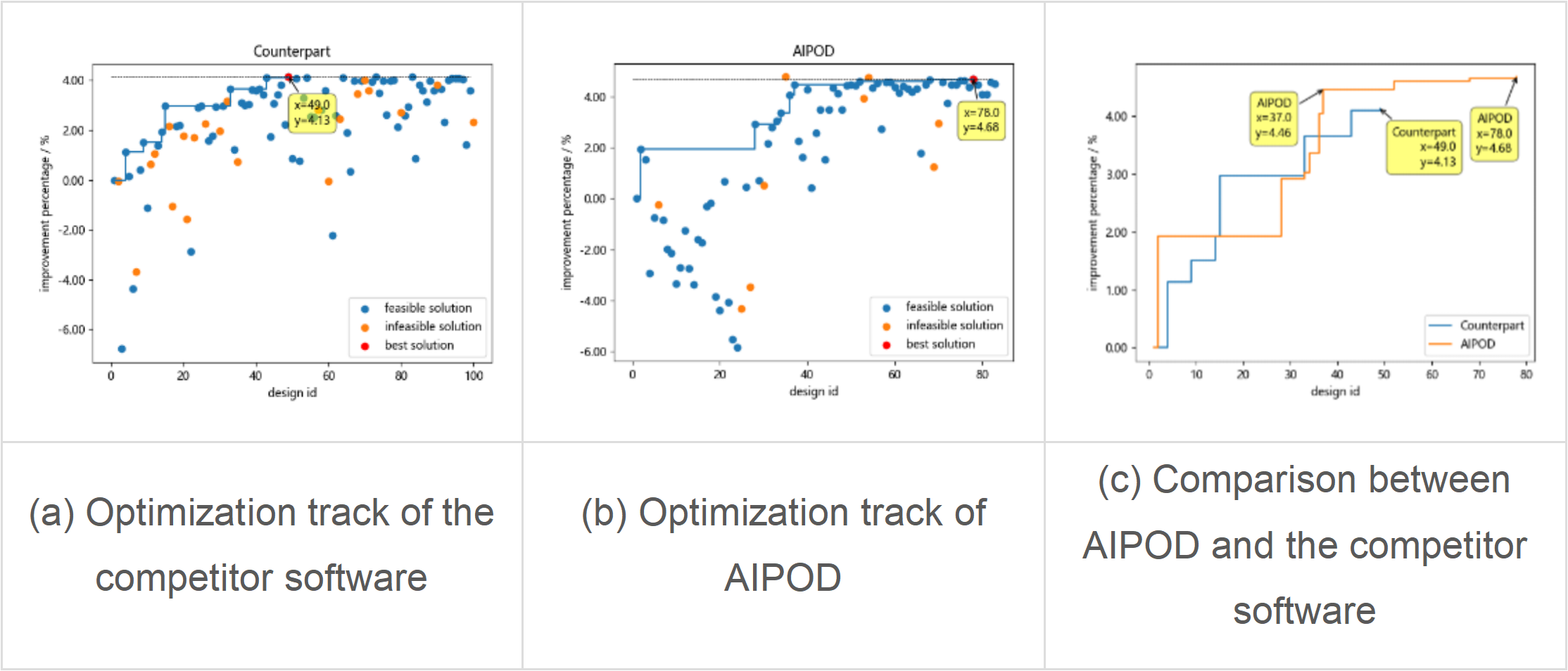

This case has eight design variables. The target variable is the minimum drag coefficient. There are two constraints, and the number of CFD calling times is limited to 100. Given the limited disk space, AIPOD performs optimization only 83 times. Table 3 describes the optimization process. After 100 times of optimization, AIPOD improves performance by 4.68%, surpassing the competitor software that improves performance by only 4.13%. The following figure shows the optimization result pressure nephograms obtained by using AIPOD and the competitor software.

Table 3 Key data in the optimization process of AIPOD and the competitor software

Pressure nephograms after ship hull optimization

The following figure shows the optimization process of AIPOD and the competitor software. In this case, the intelligent bound-break feature of AIPOD is enabled for optimization. The results show that AIPOD surpasses the competitor software in terms of optimization efficiency and effect. In addition, the bound-break feature helps design engineers find overlooked ranges for efficient design.

Optimization process of AIPOD and the competitor software

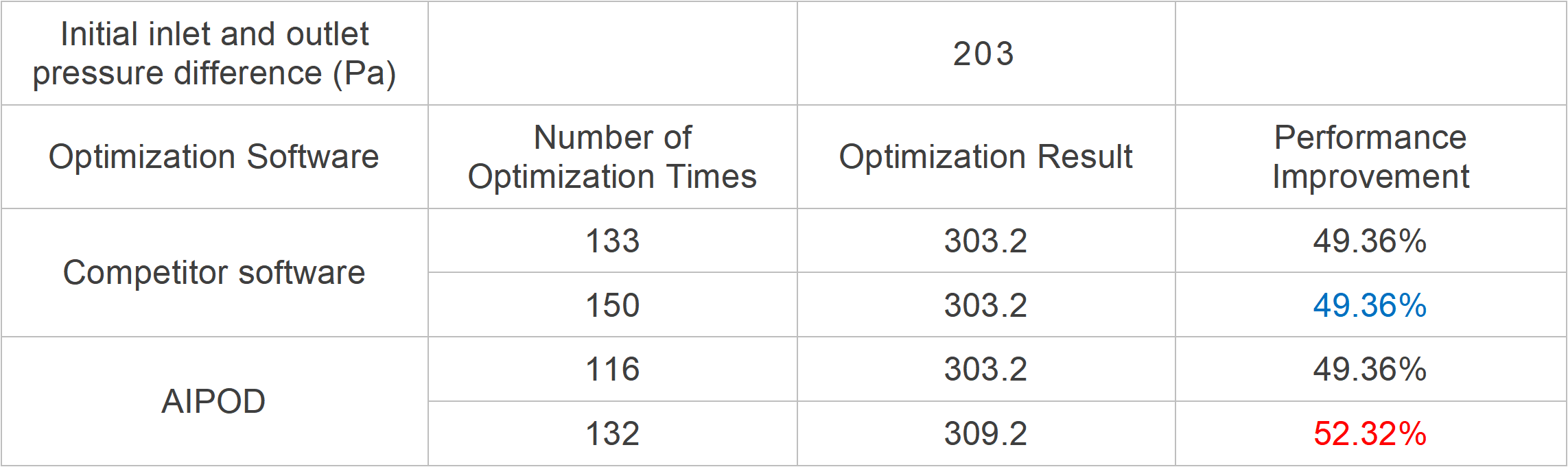

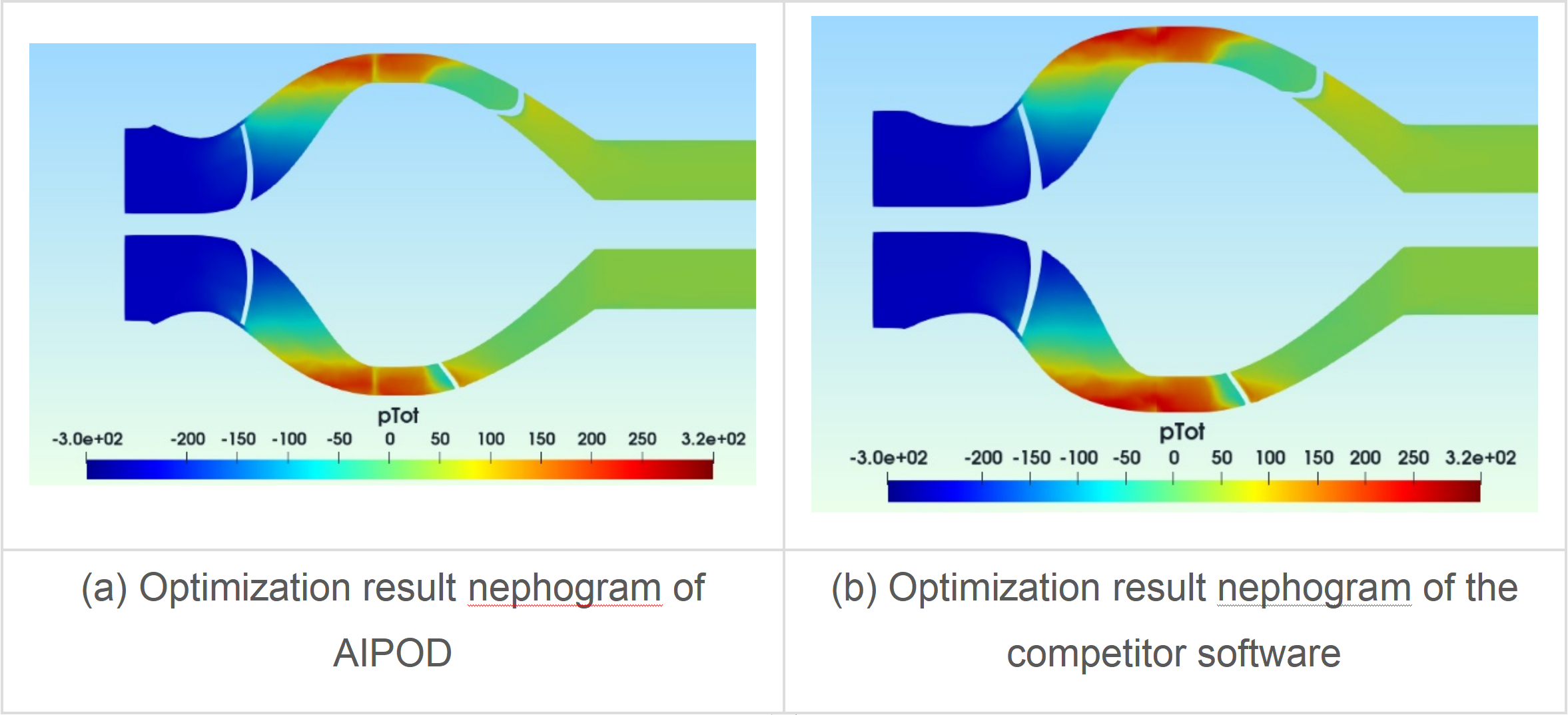

(3) Diagonal-flow fan hub optimization

This case has 14 design variables. The target variable is the maximum inlet and outlet pressure difference. There is one constraint, and the number of CFD calling times is limited to 150. Table 4 describes the optimization process. After 150 times of optimization, AIPOD improves performance by 52.32%, surpassing the competitor software that improves performance by only 49.36%. The following figure shows the optimization result pressure nephograms obtained by using AIPOD and the competitor software.

Table 4 Key data in the optimization process of AIPOD and the competitor software

Pressure nephograms after diagonal flow fan hub optimization

The following figure shows the optimization process of AIPOD and the competitor software. The competitor software showed rapid performance improvement in the early phase. However, its subsequent performance improvement is slow, and no further improvement was observed after the local extremum was reached. By contrast, AIPOD achieved sustained optimization with high efficiency.

Optimization process of AIPOD and the competitor software

In this case, the intelligent bound-break feature of AIPOD is enabled for optimization. Table 5 shows that although the competitor software has captured the values of several design variables that contribute to the optimal design, these values can be used only as constraint values due to the limitation of the pre-defined value ranges. As a result, the competitor software fails to improve the optimization result further.

Table 5 Pre-defined value ranges and the values used by AIPOD and the competitor software to generate the optimal design

(4) Geometry optimization of an air intake duct

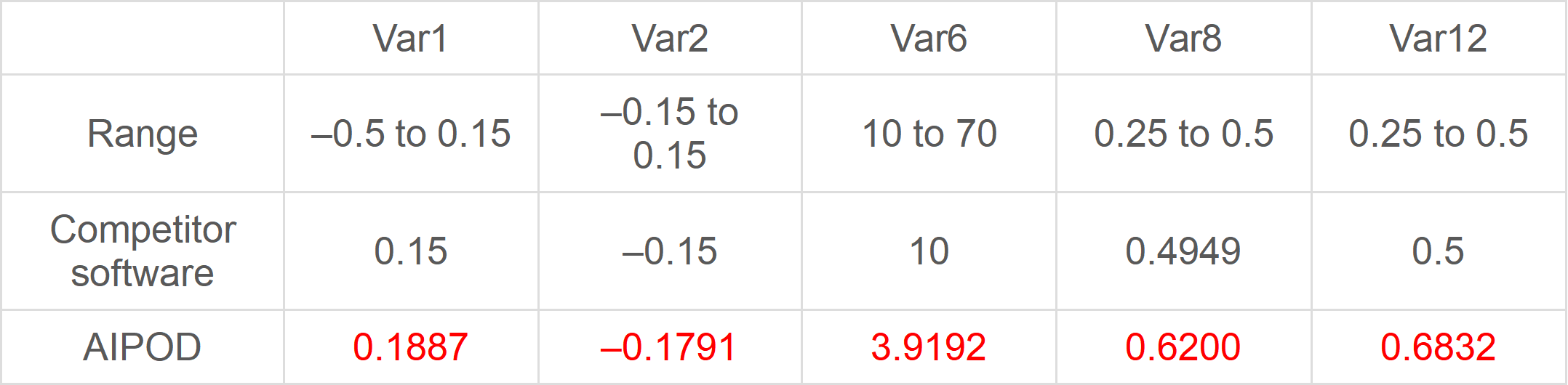

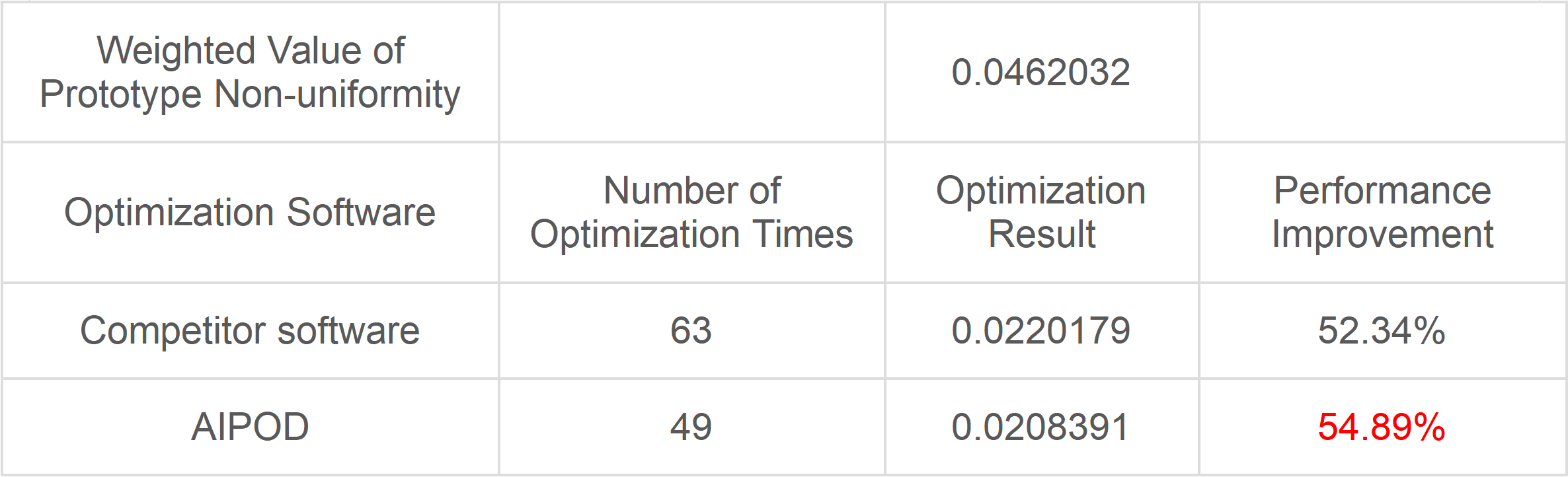

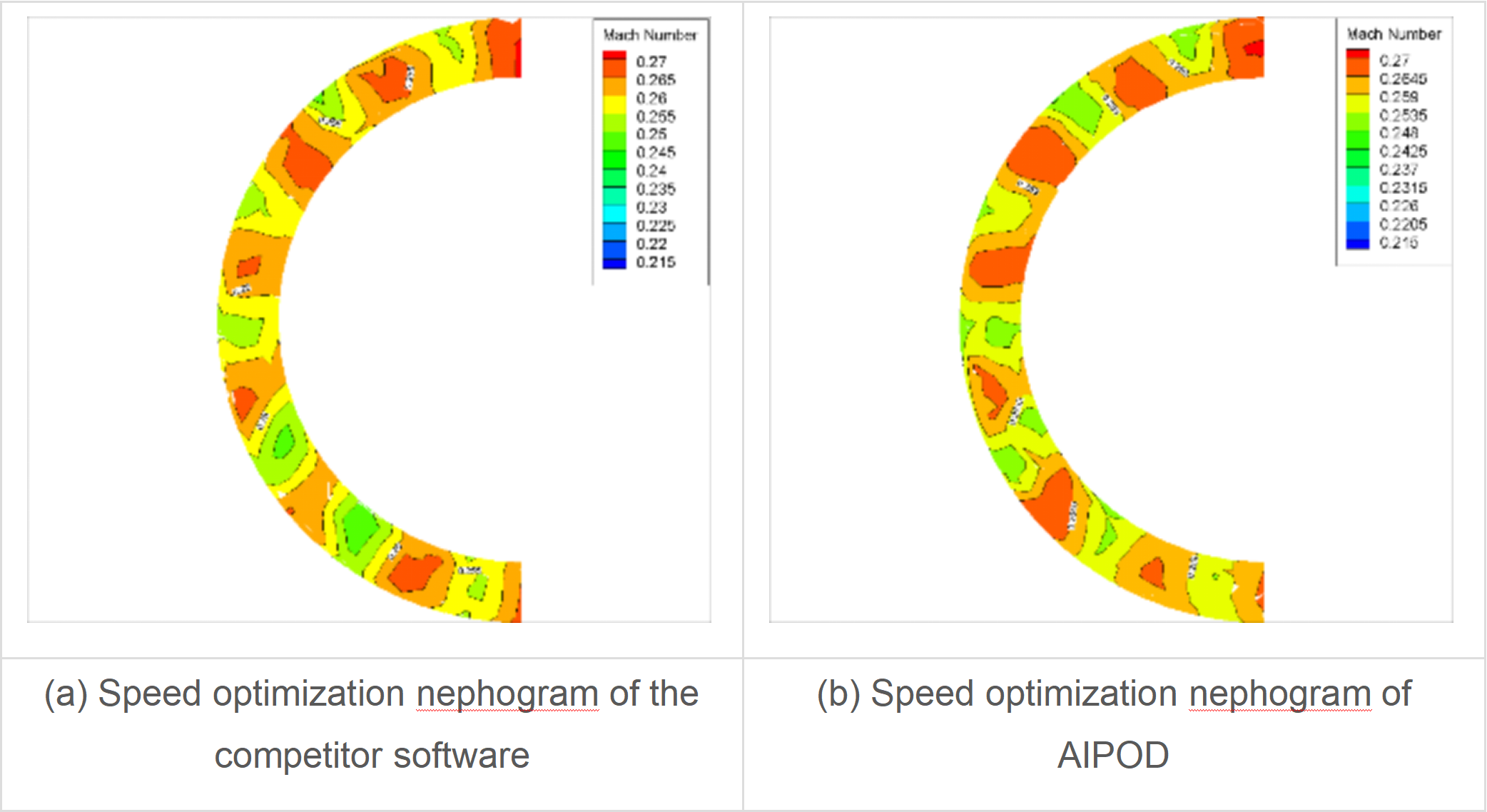

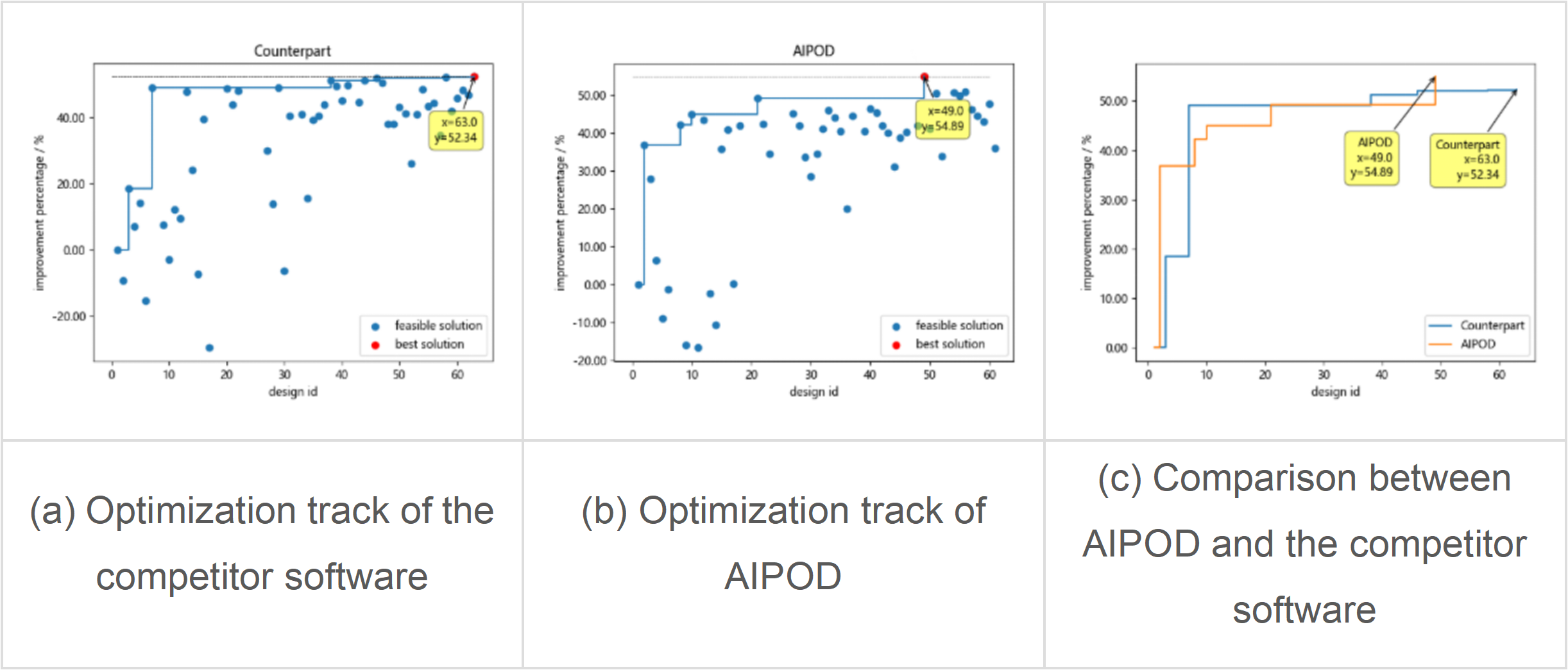

This case has five design variables. The target variable is the minimum weighted value for the total outlet pressure non-uniformity and outlet speed non-uniformity. The number of CFD calling times is limited to 60. Table 6 describes the optimization process. After 60 times of optimization, AIPOD improves performance by 54.89%, surpassing the competitor software that improves performance by only 52.34%. The following figure shows the optimization result nephograms obtained by using AIPOD and the competitor software.

Table 6 Key data in the optimization process of AIPOD and the competitor software

Nephogram for the geometry optimization of an air intake duct

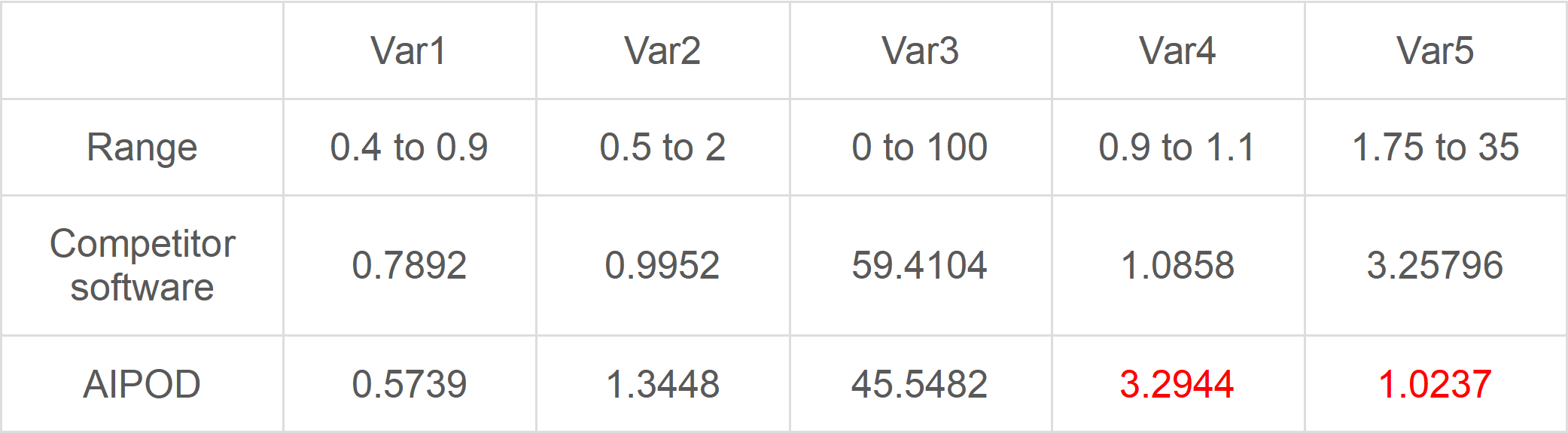

In this case, the intelligent bound-break feature of AIPOD is enabled for optimization. As shown in Table 7, if the design parameter ranges are improper, the optimization engine of the competitor software does not extend the range for efficient and feasible optimization. By contrast, the SilverBullet algorithm with bound-break enabled can quickly break the optimization barriers caused by improper range settings by engineers.

Table 7 Pre-defined value ranges and the values used by AIPOD and the competitor software to generate the optimal design

The following figure shows the optimization process of AIPOD and the competitor software. The competitor software surpassed AIPOD only in the early phase. However, the competitor software reached the local extremum soon and failed to improve the optimization further. By contrast, AIPOD achieved sustained optimization with high efficiency.

Optimization process of AIPOD and the competitor software

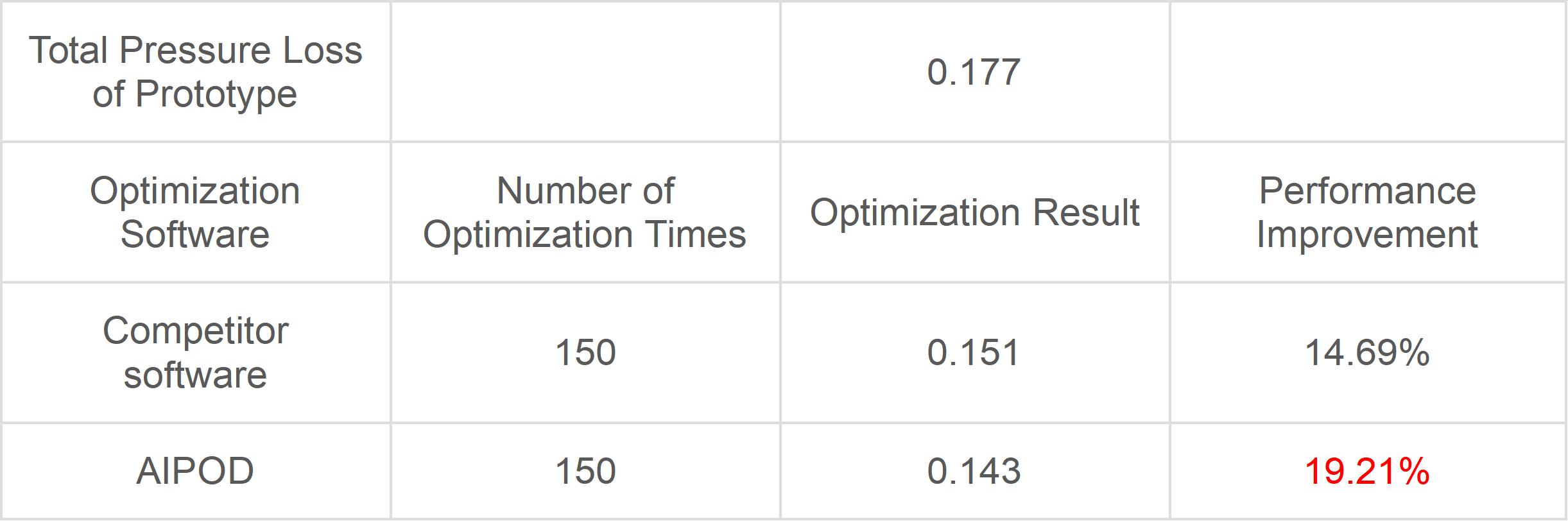

(5) Fan blade optimization

This case has nine design variables. The target variable is the minimum loss of total pressure. There are three constraints, and the number of CFD calling times is limited to 150. Table 8 describes the optimization process. After 150 times of optimization, AIPOD improves performance by 19.21%, surpassing the competitor software that improves performance by only 14.69%.

Table 8 Key data in the optimization process of AIPOD and the competitor software

In this case, the intelligent bound-break feature of AIPOD is enabled for optimization. As shown in Table 9, the pre-defined value ranges of the design variables in this case are proper, and AIPOD and the competitor software adopted values in the pre-defined ranges to generate the optimal design. Although the bound-break feature is enabled, AIPOD did not blindly break the boundaries. Instead, AIPOD selected the values that contributed to the optimal design, no matter whether the values fell in or out of the pre-defined ranges.

Table 9 Pre-defined value ranges and the values used by AIPOD and the competitor software to generate the optimal design