请输入正确的账号名!

密码格式有误请验证!

请输入正确的账号名!

请输入正确的账号名!

请输入正确的单位名称!

请输入....!

请输入....!

请输入....!

请输入....!

请输入....!

目前您的账号暂时还不能进行登录哦~

对此我们深感抱歉!但还请您耐心等待审核通过

注册信息审核通过后我们将会在第一时间以邮件的方式通知您

请输入正确的账号名!

请输入....

请输入....!

请输入....!

请输入....!

密码格式有误请验证!

密码格式有误请验证!

请输入....!

AIPIPE is a unified platform that is independently developed by Nanjing Tianfu Software Co., Ltd. for intelligent pipe design and O&M. AIPIPE is oriented to the optimization of pipe networks in the energy and power, petrochemical, nuclear power, hydraulic engineering, and other related fields. In addition, AIPIPE is dedicated to building an intelligent pipe platform that integrates mechanical analysis, design optimization, health monitoring, and O&M services. AIPIPE deeply integrates the existing core finite element algorithms in the pipe industry to implement features such as pipe modeling, special component processing, static force analysis for pipes, stress checking, and spring selection.

The latest AIPIPE version 2022R1-SP1 has the following improvements compared with the 2022R1 version:

(1) Enhanced model interaction on UI. Users can select a pipe at the specified position to view its data.

(2) Improved computing precision. The computing precision for special components, such as reducing tees and elbows, is markedly improved. The stress checking algorithm is optimized. The self-weight simulation of pipes at the coating and insulating layers is more accurate.

(3) Improved software stability. Defects that may affect the software stability are fixed.

HIGHLIGHTS

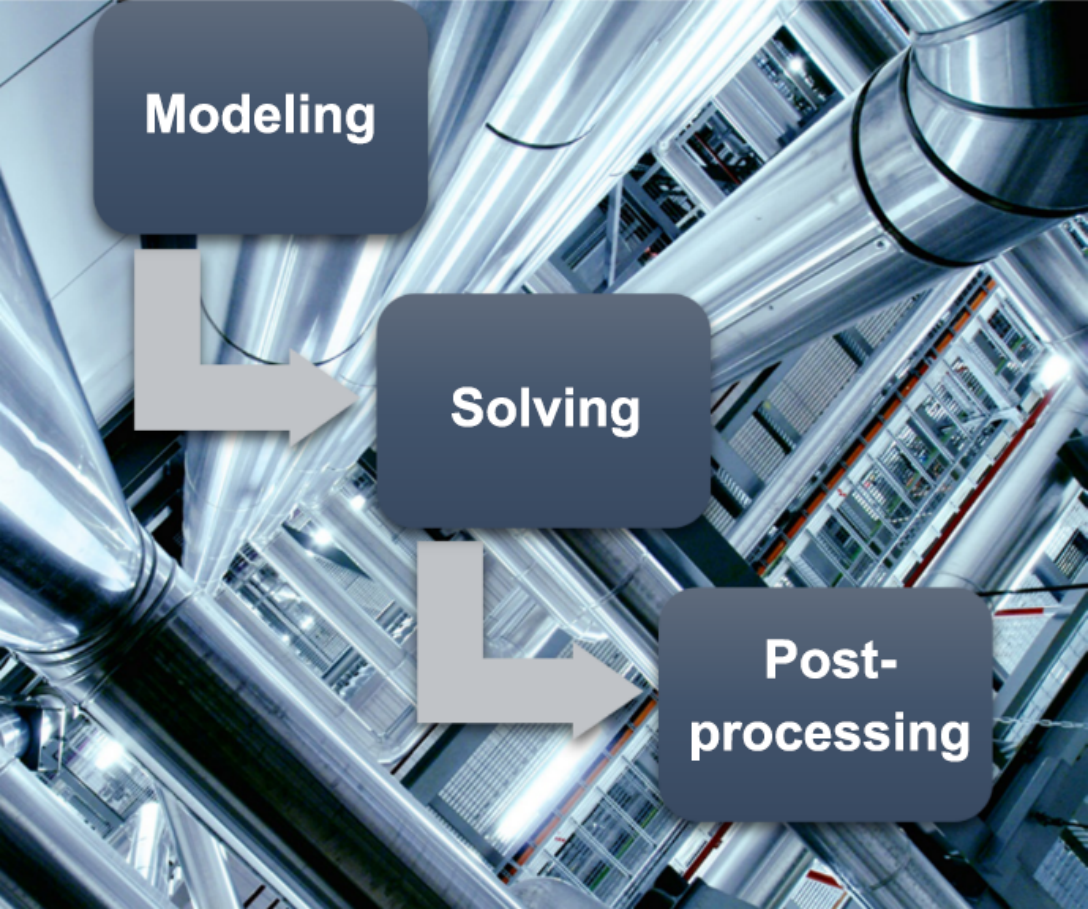

(1) Efficient process module design

AIPIPE properly associates core pipe analysis modules, such as pipe modeling, multi-condition design, solving, post-processing, and visualization. The modules are independent of each other and can deliver data and commands to each other. This prevents page stacking because each module has its own page. This also improves page interaction, ensures a smooth and convenient process, and minimizes the software learning cost.

Figure 1 AIPIPE usage process

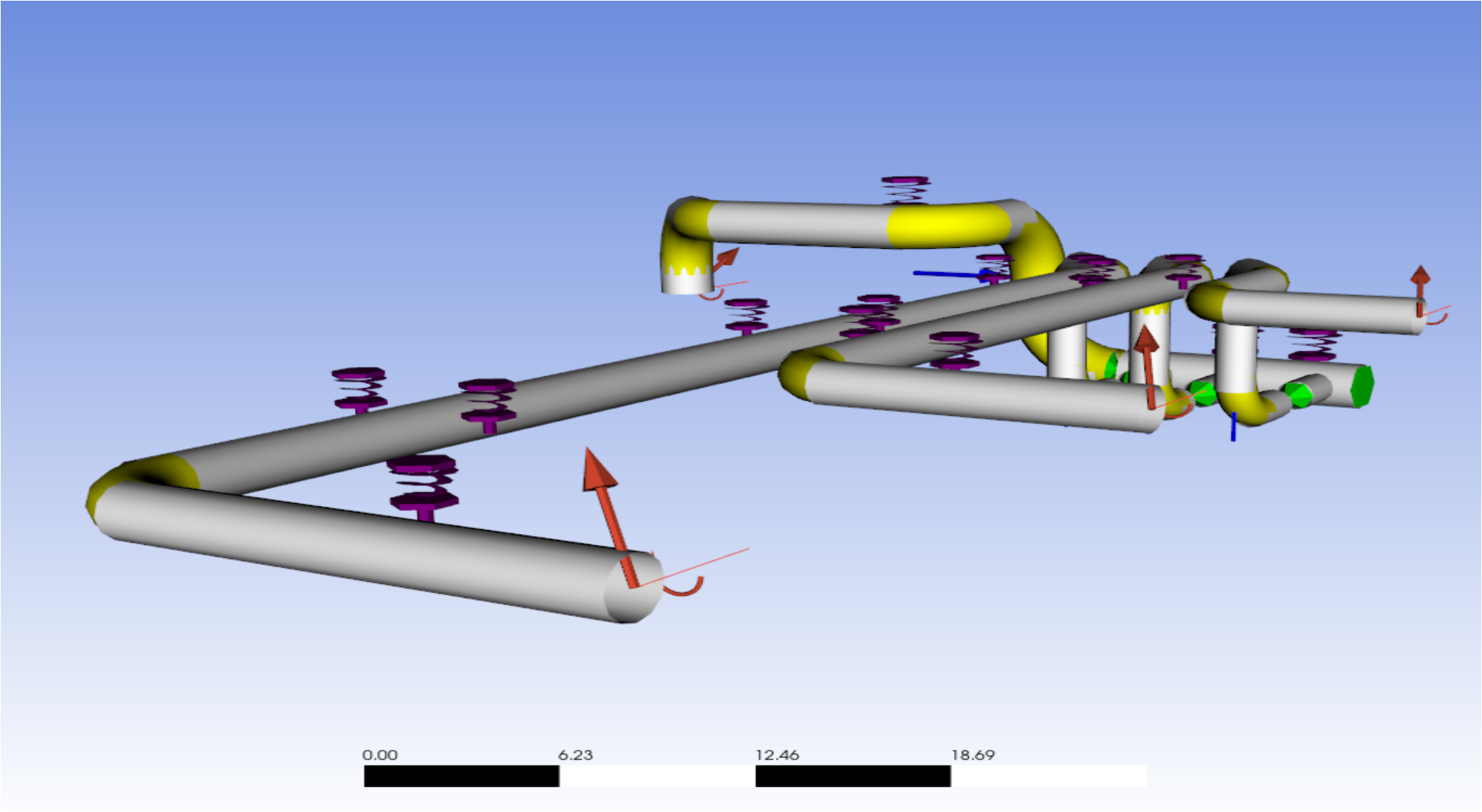

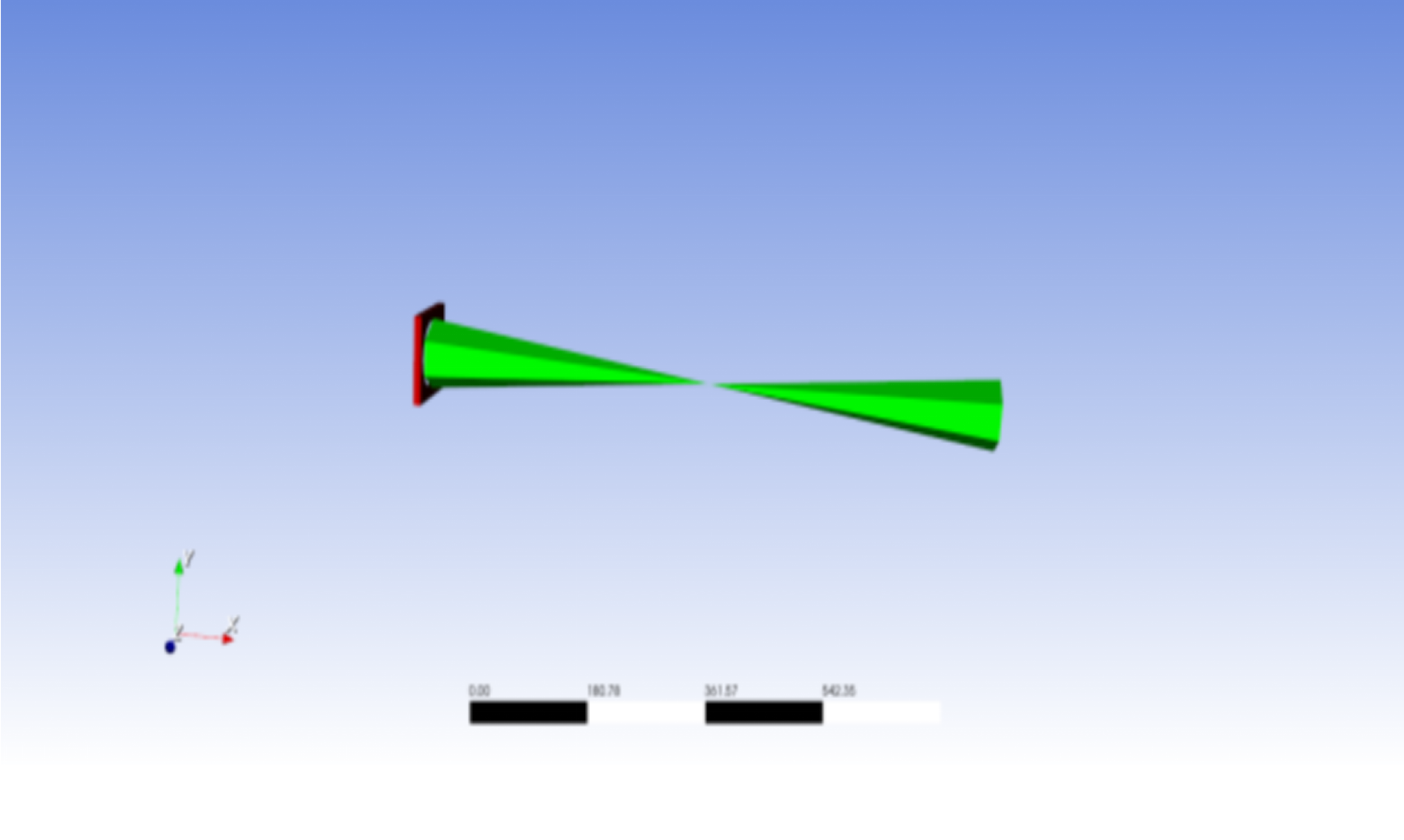

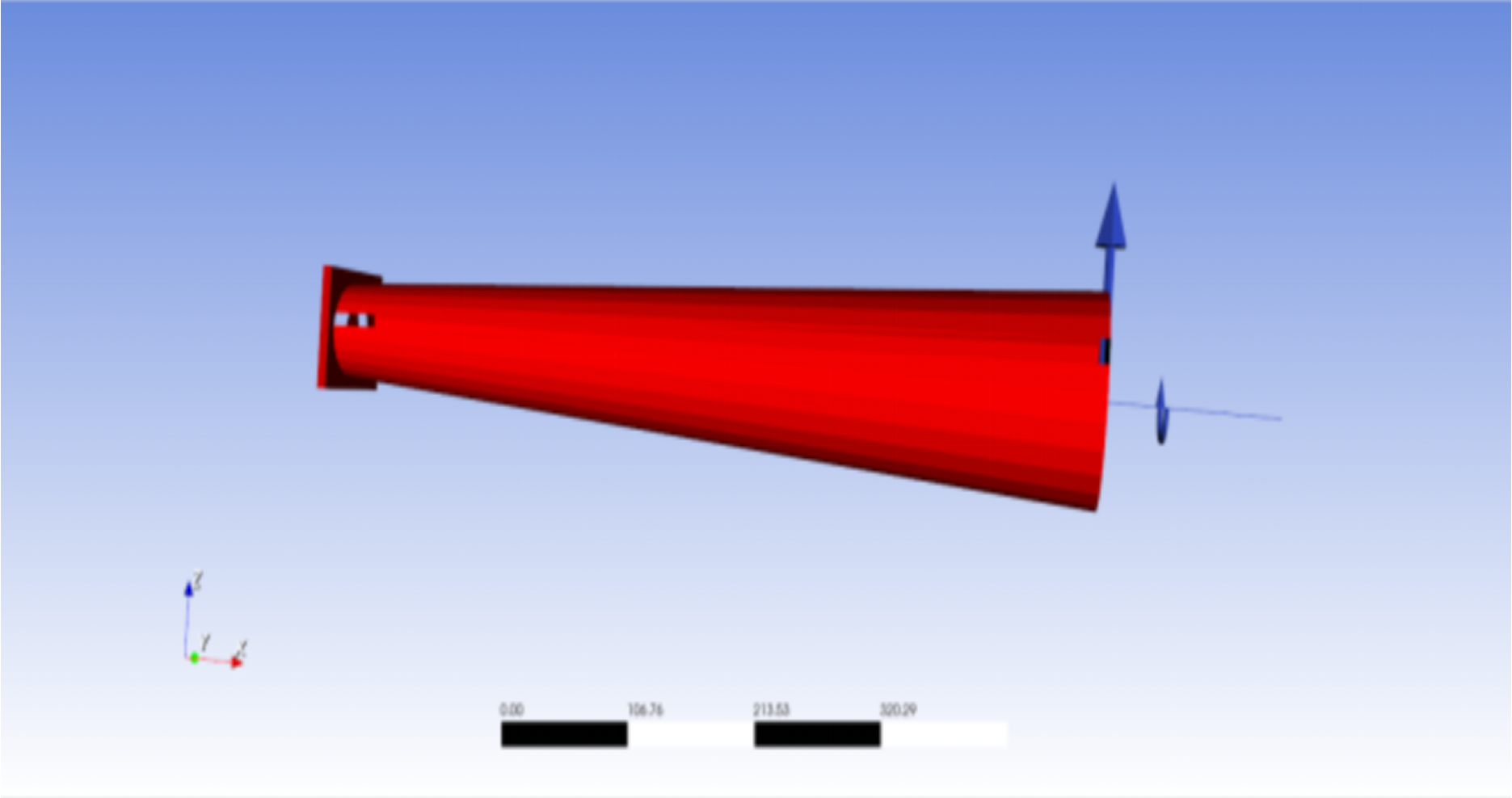

(2) Focus on core pipe analysis technologies

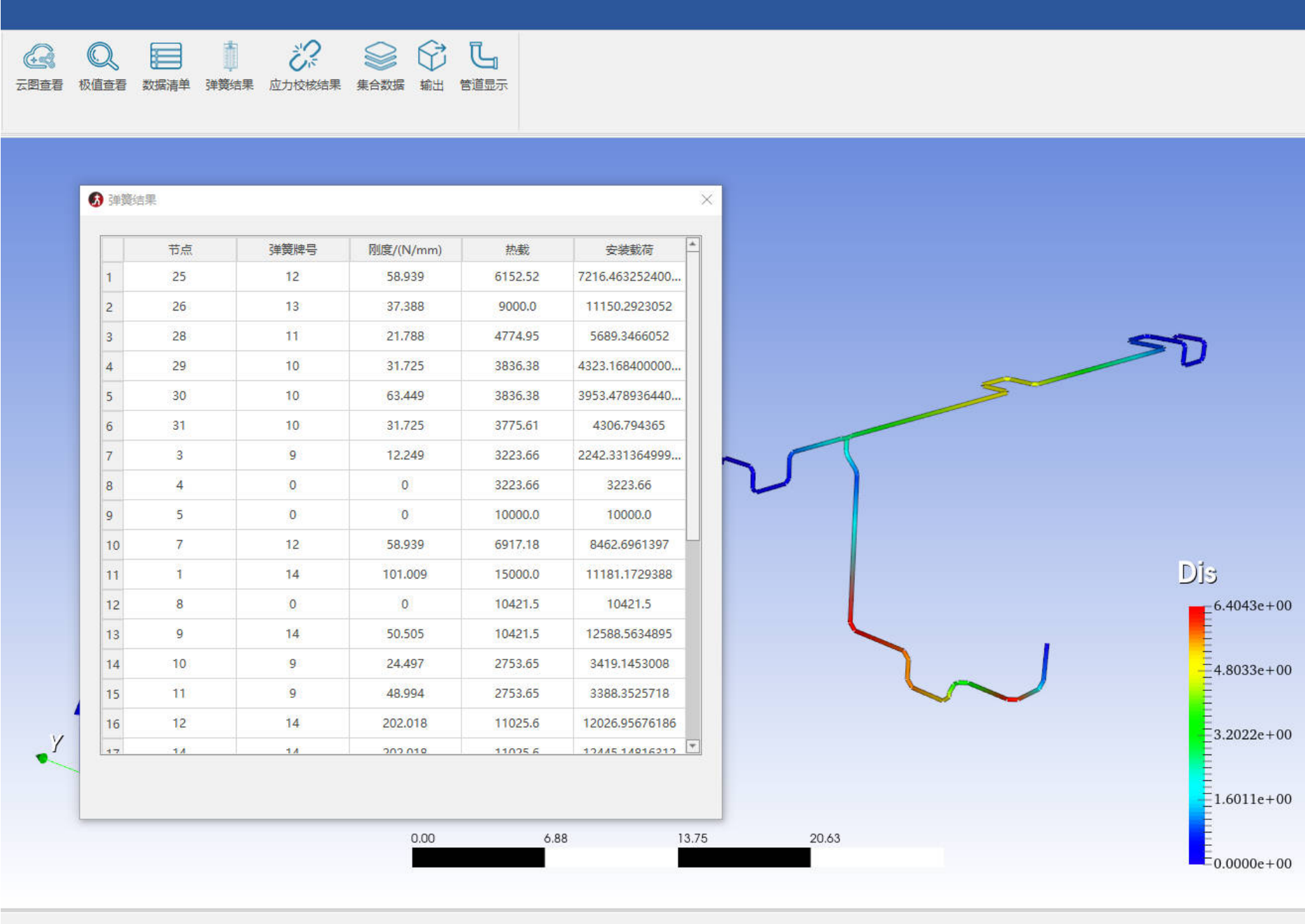

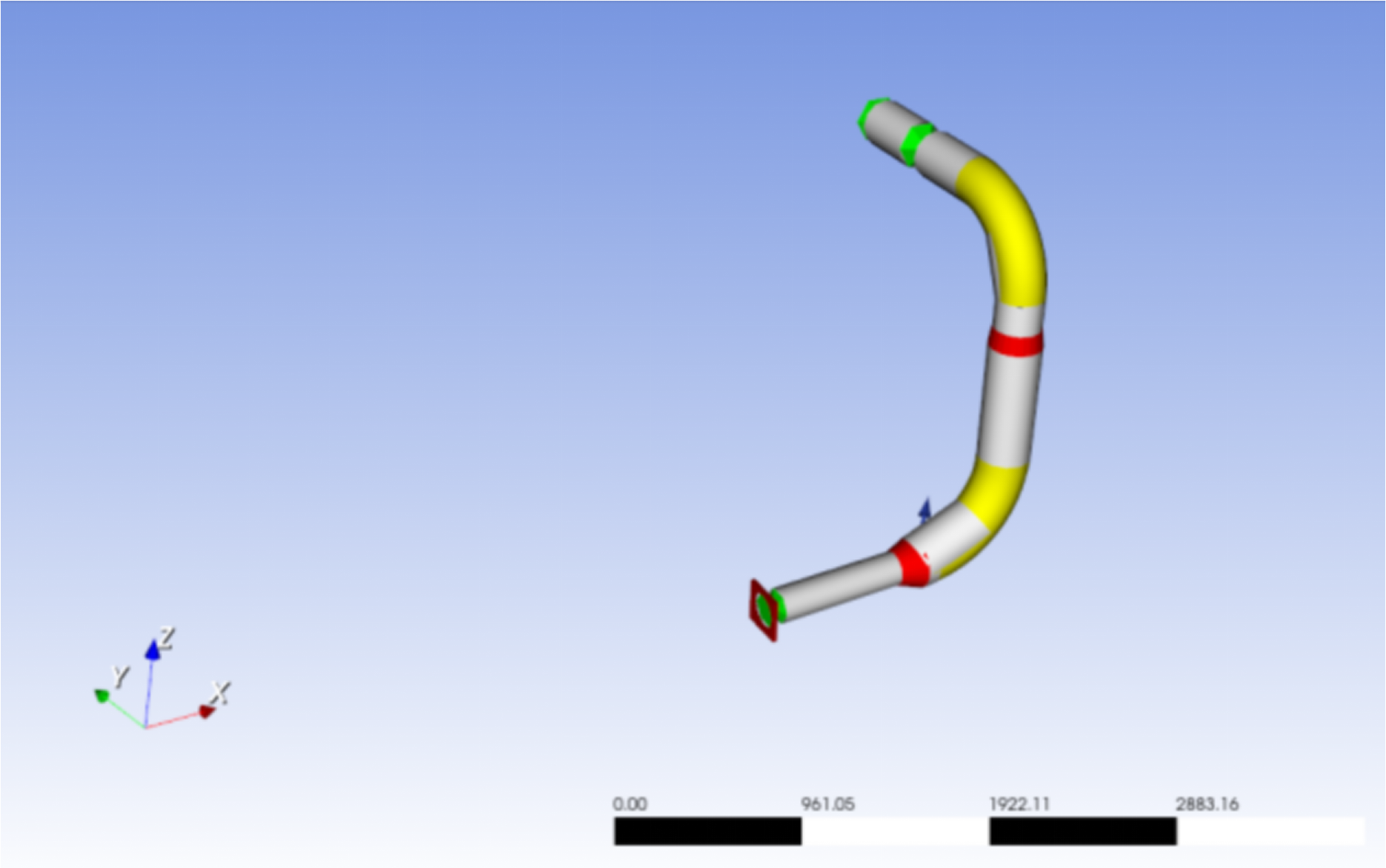

AIPIPE focuses on core pipe analysis technologies, utilizes the beam element theory, and develops a dedicated element database that can process special components, such as elbows, reducers, rigid components, and three-way pipes. Based on pipe specifications and industrial standards, AIPIPE is developed with key pipe design features, such as spring selection, batch design and condition analysis, and stress checking.

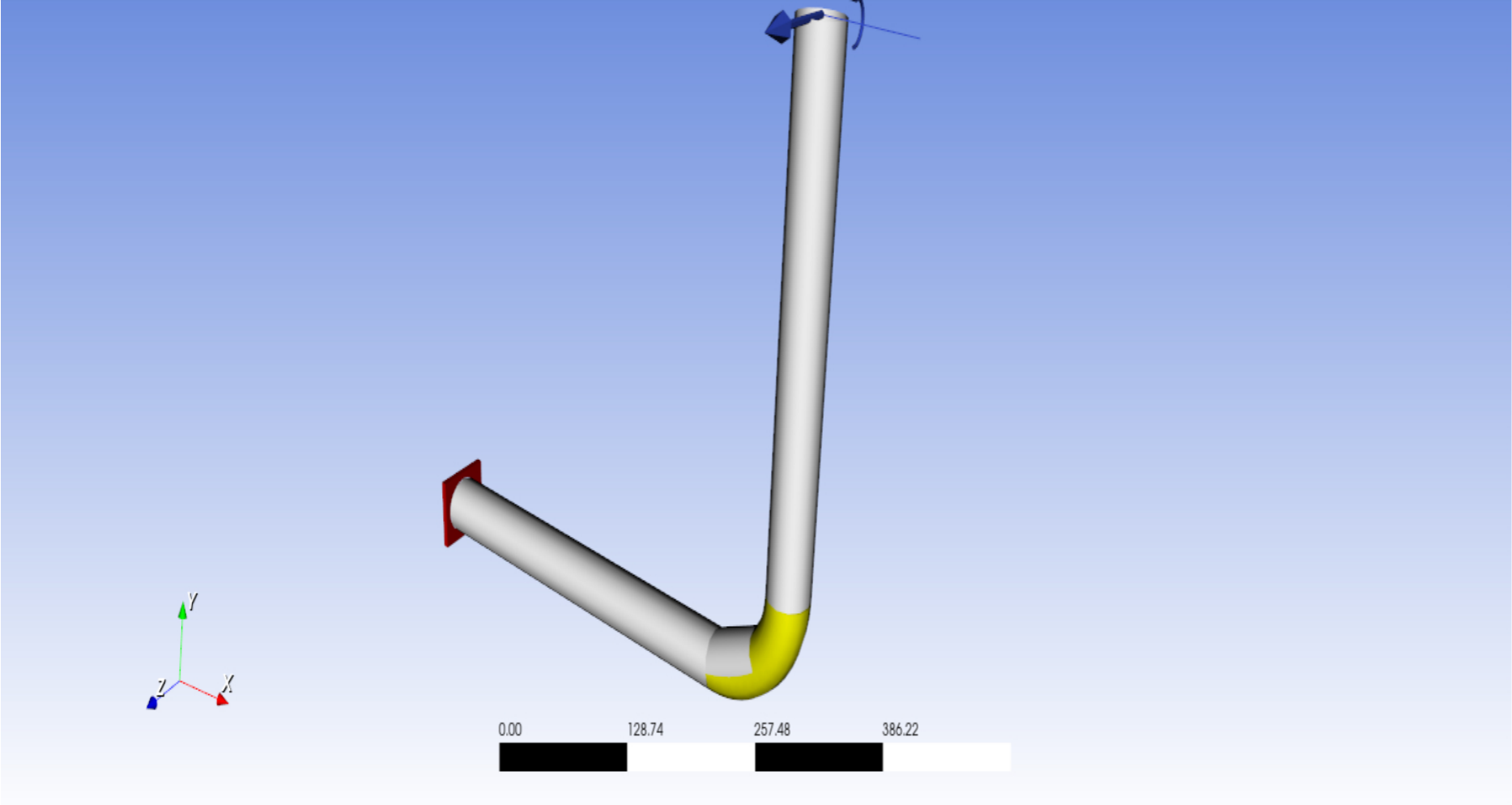

Figure 2 Various types of pipe components

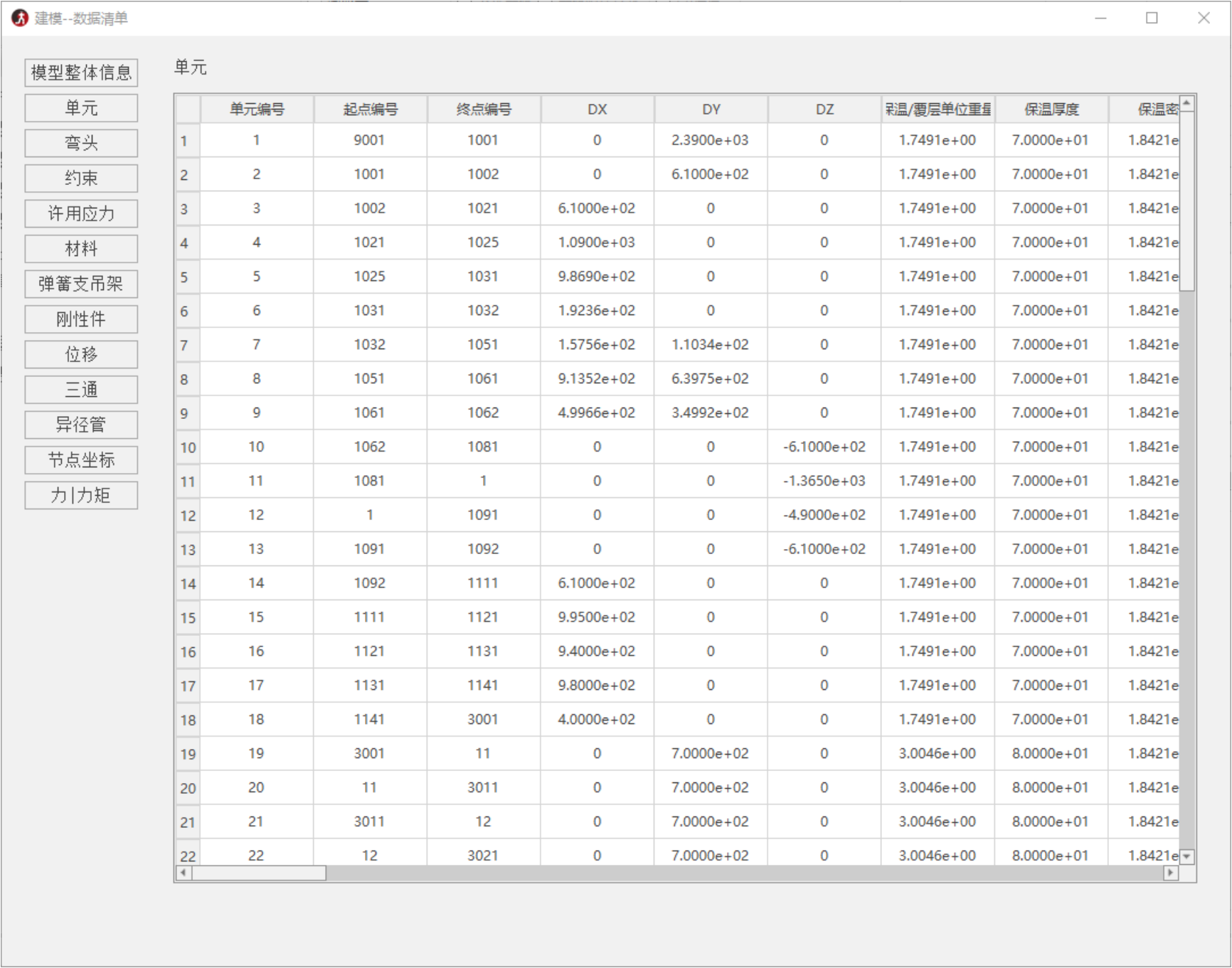

(3) Accurate data management

The design of each pipe involves more than 200 parameters, including parameters related to the geometry, material, component, load, constraint, and environment. The massive volume of data in the pipe network must be managed and used properly to ensure efficient modeling and analysis. AIPIPE integrates 300 material databases and Chinese variable spring standard databases. As a result, AIPIPE can parse CII and other model data and manage data in an accurate and efficient manner.

Figure 3 Retrieval of pipe model data

(4) Easy access to model data

AIPIPE provides a button in the modeling, post-processing, visualization, and other modules for users to query all types of data reports anytime. Users can query the processing results of multi-condition design by condition. Users can also switch between models and result distribution nephograms in different viewports. These features aim to help users easily access different types of model data, reduce design errors, quickly locate design defects, and improve design efficiency.

Figure 4 Data post-processing and visualization

CASE 1 - Stress analysis of basic pipes

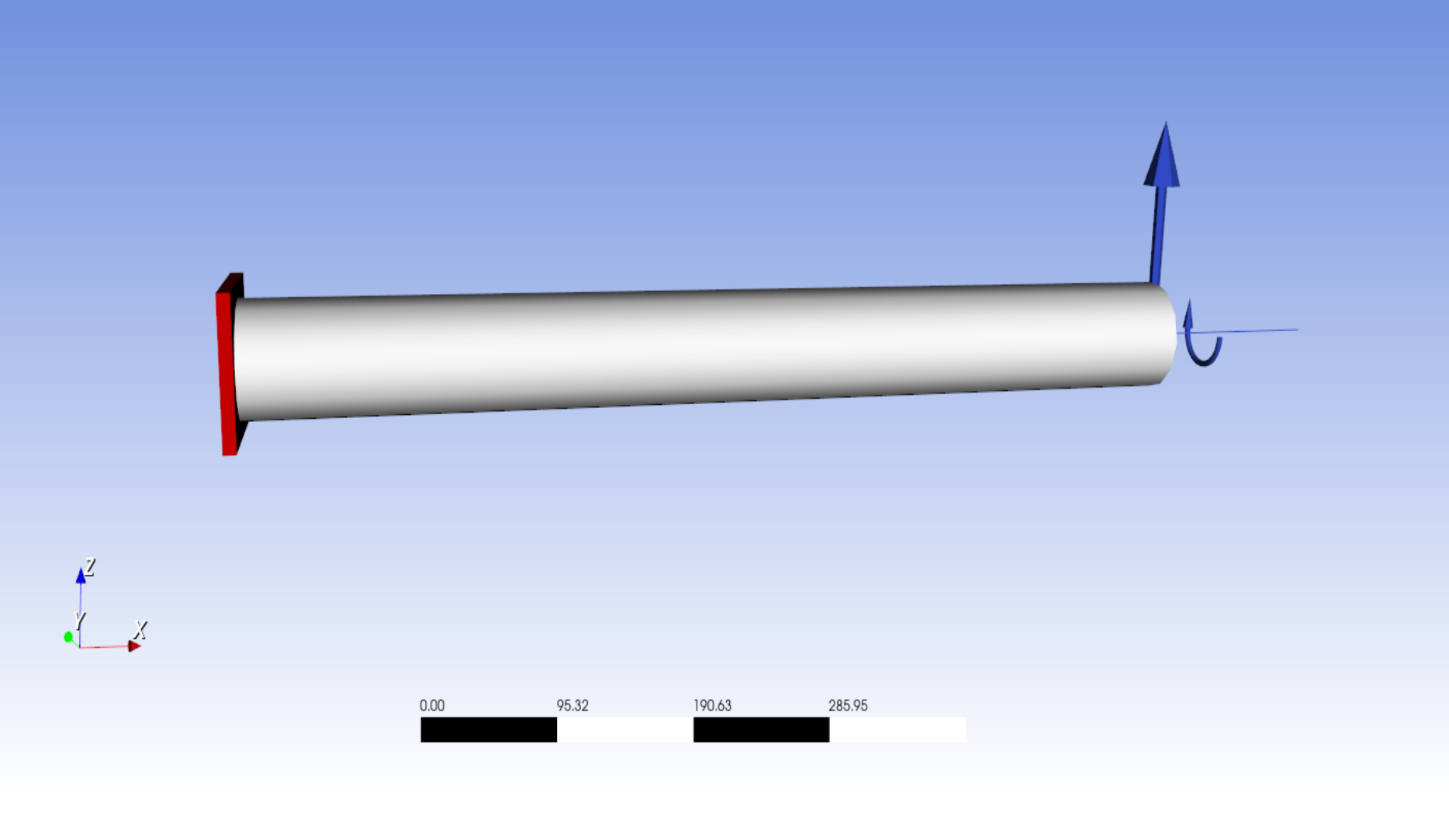

(1) Stress analysis of a common pipe

(2) Stress analysis of a rigid component

(3) Stress analysis of a reducer

(4) Stress analysis of an elbow

CASE 2 - Stress analysis of composite pipes

(1) Stress analysis of a composite that contains various pipe components

(2) Automatic selection of variable springs